Направление применения: Используется для изготовления статора серводвигателя.

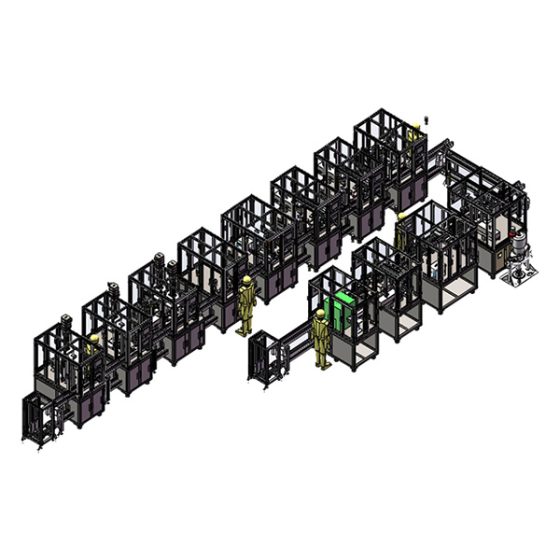

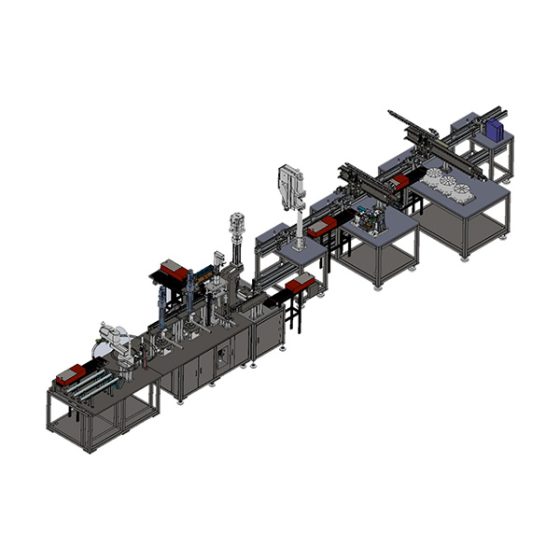

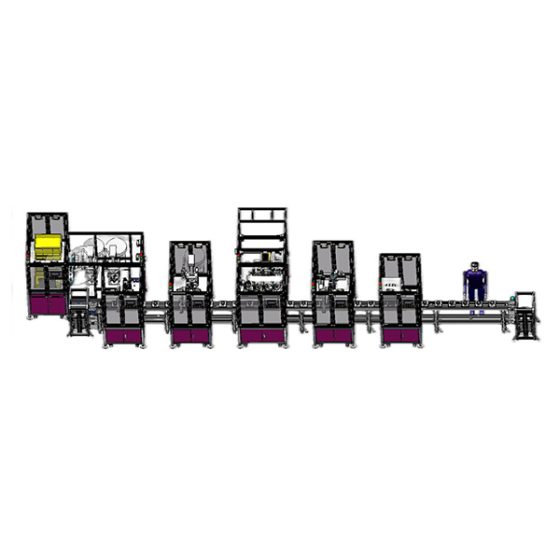

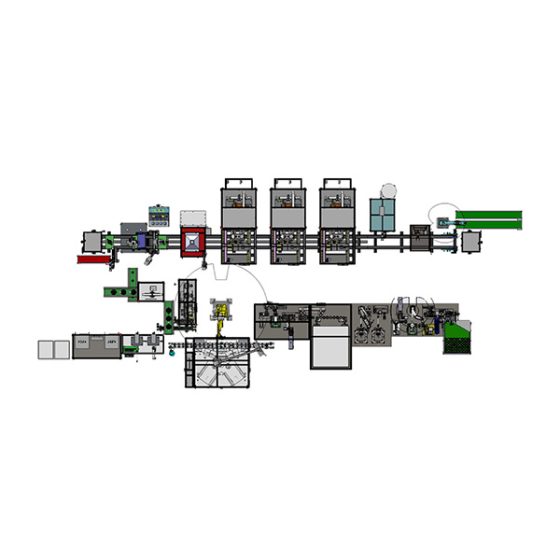

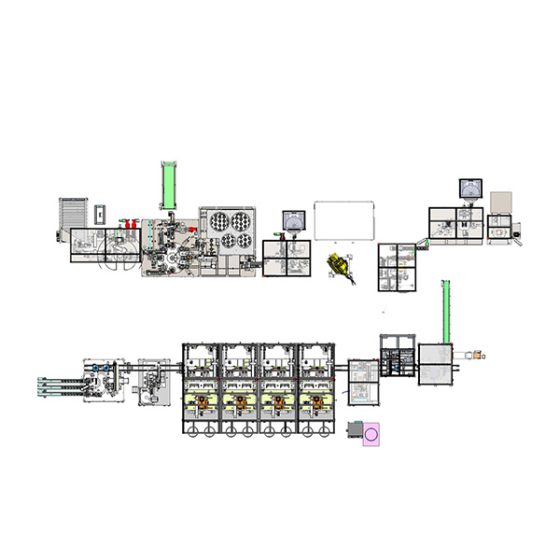

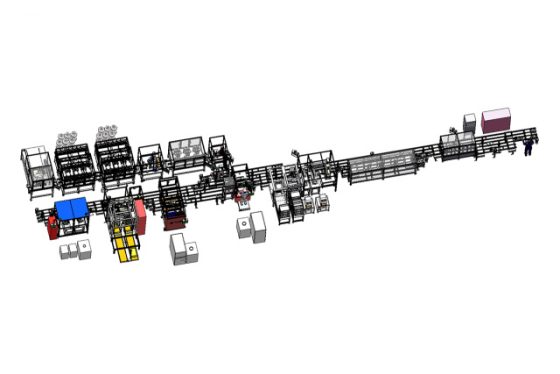

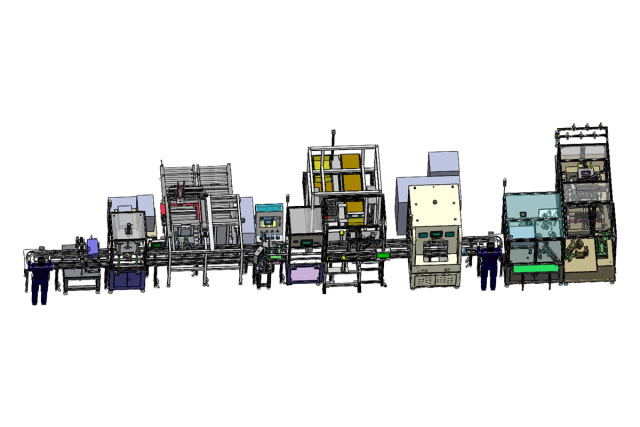

Конфигурация производственной линии: Эта программа использует механическую конструкцию для транспортировки статора для соединения различных производственных модулей, с тактовым временем ≤60С (может быть модернизирована до 30S за счет увеличения количества намоточных станков и другого оборудования), оснащена загрузочной машиной, станок для намотки статора, Ротационная дисковая паяльная машина, лазерный сварочный аппарат, станок для сборки печатных плат, Машина для тестирования производительности двигателя, машина для загрузки ящиков, Горячая гильза в оболочку машины, лазерная машина для кодирования, конвейерная линия из ДПК.

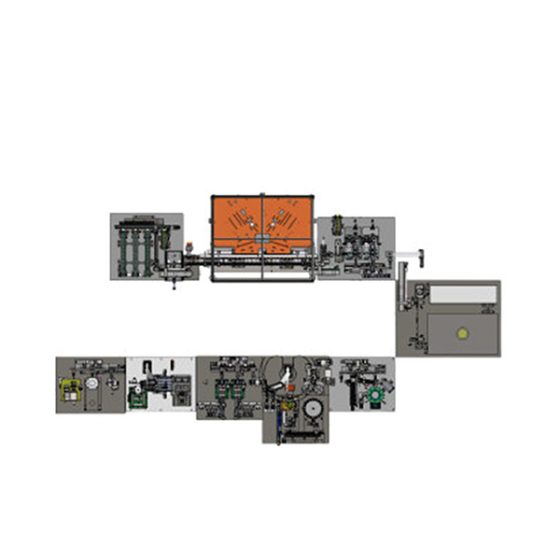

Кадровые: Когда линия статора работает, Он должен управляться двумя людьми, оператор 1 отвечает за проверку внешнего вида готовой продукции, Упаковка и пополнение материала линии, и оператор 2 отвечает за раунд предварительного скремблирования блока статора. Размер всей линии составляет около 13270 мм x 4100 мм, а высота оборудования составляет 1800мм.

Преимущества производственной линии: Автоматическая линия с сервоприводом может помочь производителям повысить эффективность и качество производства, Сокращение ручного вмешательства, Повышение качества и стабильности продукции для достижения эффективного автоматизированного производства.

- Подробнее о продукте

- Производственный процесс

Загрузка сердечника→Скелет в сборе→Контакт в сборе→Намотка провода→Погружение в флюс→Пайка PIN-контактом→Тест на производительность→Бумажная наклейка→Сращивание и формирование круга→Статор в кольцо→Код лазерного сканирования статора→Загрузка и сборка печатной платы→Пайка печатной платы→Лужение диска на печатной плате→Комплексное тестирование статора→Загрузка корпуса→Лазерная маркировка корпуса→Нагревательная рубашка в корпусе→Определение высоты статора→Разрядка статора→охлаждение→Поток линии ДПК→Ручная разгрузка и упаковка

Предыдущая: Бесщеточная машина для намотки двигателя

Следующий: Автоматическая линия статора EPS

Балансировочные станки JZABM

Балансировочные станки JZABM