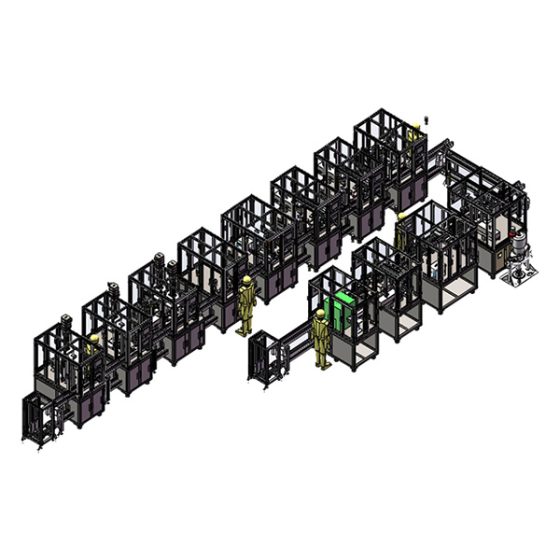

The rotary motor stator automatic line is mainly used to manufacture rotary motor stator with high efficiency and precision, and complete the stator winding, welding, testing and other processes. This production line can improve production efficiency, reduce production cost, Обеспечение качества продукции, и обладает преимуществами высокой эффективности, устойчивость, надёжность, and high degree of automation.

Application direction: Efficient and precise production of rotary motor stator, complete stator winding, welding, testing and other processes.

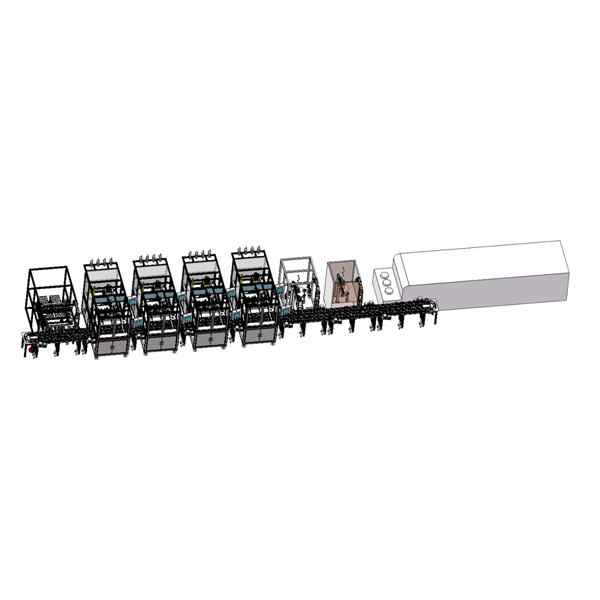

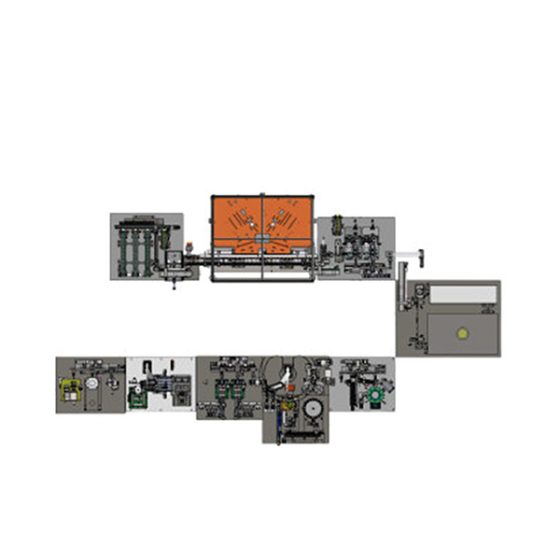

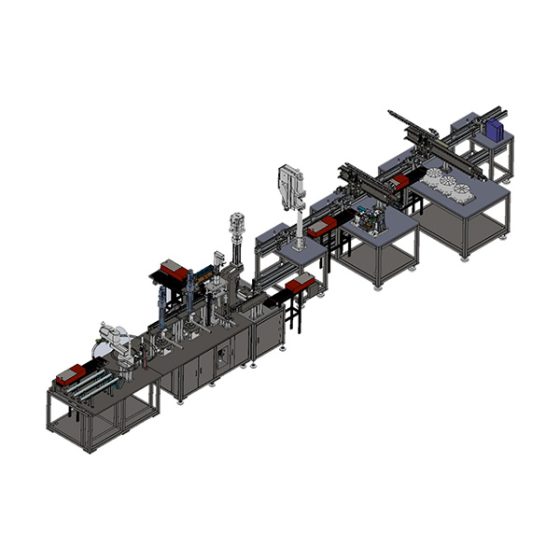

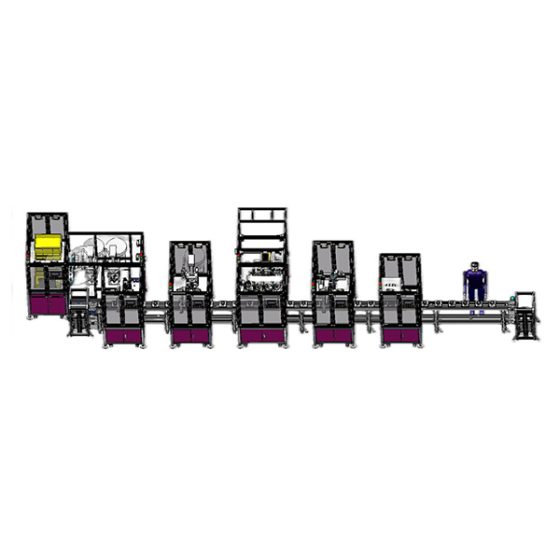

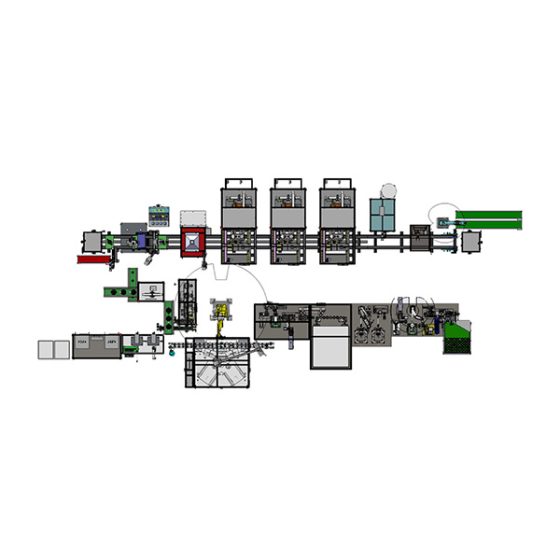

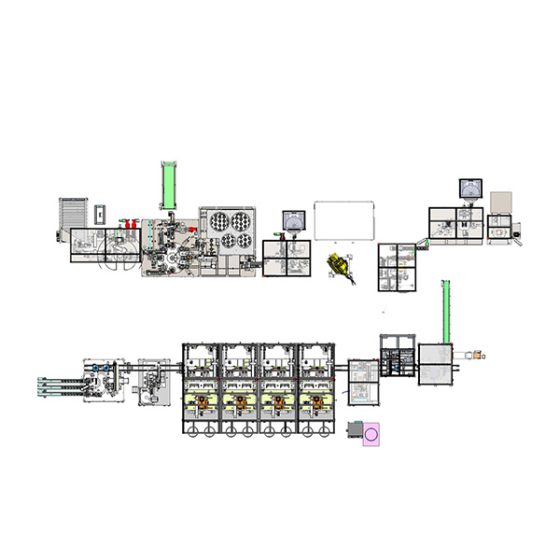

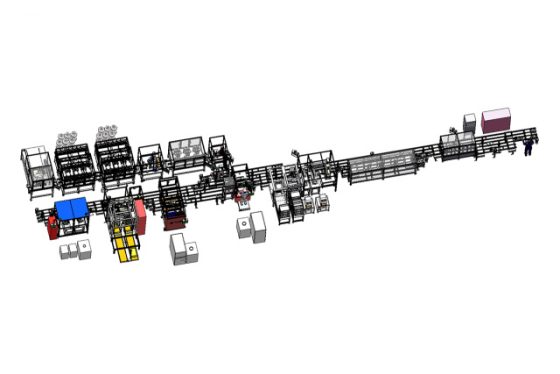

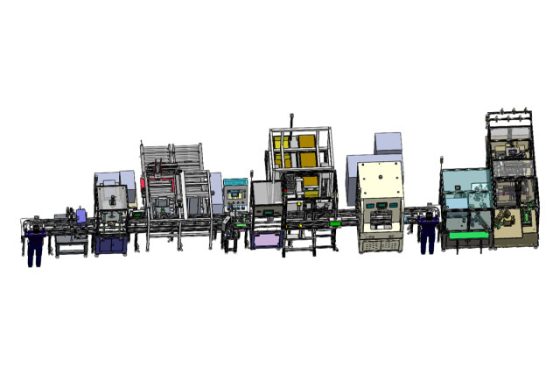

Production line structure: This program adopts mechanical structure to convey the stator to connect the production modules, the production line beat ≤ 16S/PCS Equipped with a stator loading and unloading machine, four four-station stator winding machine with automatic loading and unloading, a terminal soldering machine (with CCD detection), Машина для тестирования производительности двигателя, a set of WPC conveyor line. The size of the whole line is about 12500mmx2700mm, а высота оборудования составляет 1800мм.

Преимущества производственной линии: the production line can improve production efficiency, снизить производственные затраты, Обеспечение качества продукции, и обладает преимуществами высокой эффективности, устойчивость, надёжность, автоматизация и так далее.

Stator loading and unloading machine sweeping code → sweeping code stator winding sweeping code PIN foot welding CCD inspection → sweeping code motor performance test → sweeping code drop paint curing

Балансировочные станки JZABM

Балансировочные станки JZABM