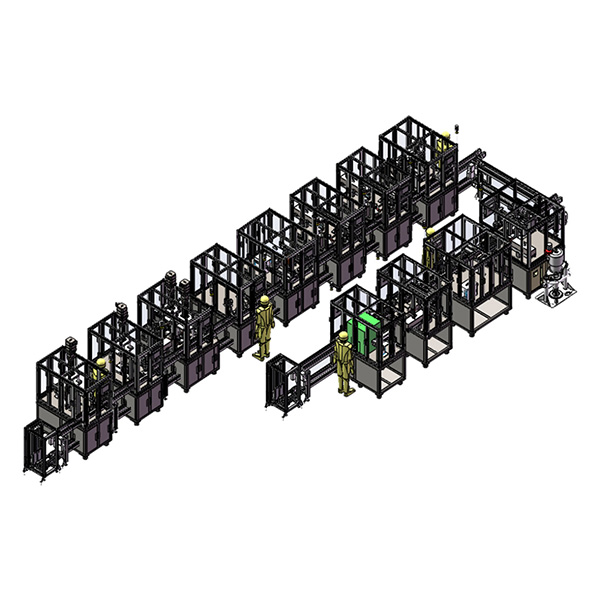

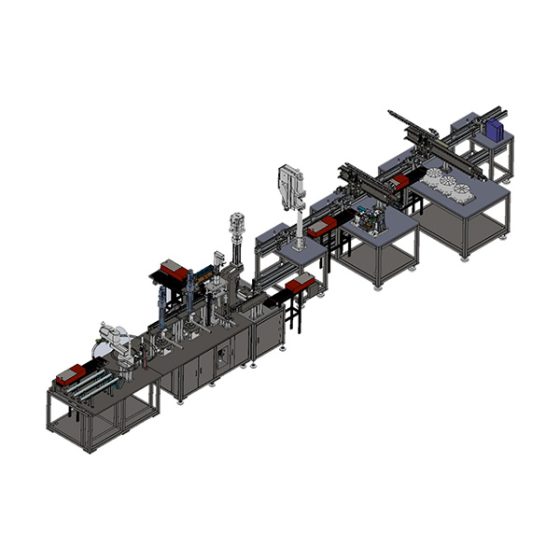

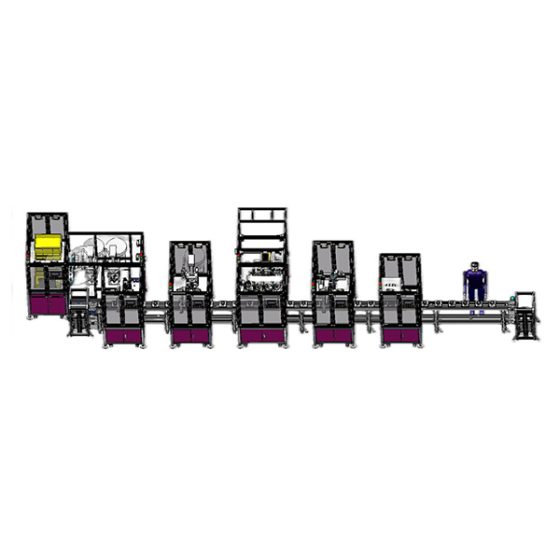

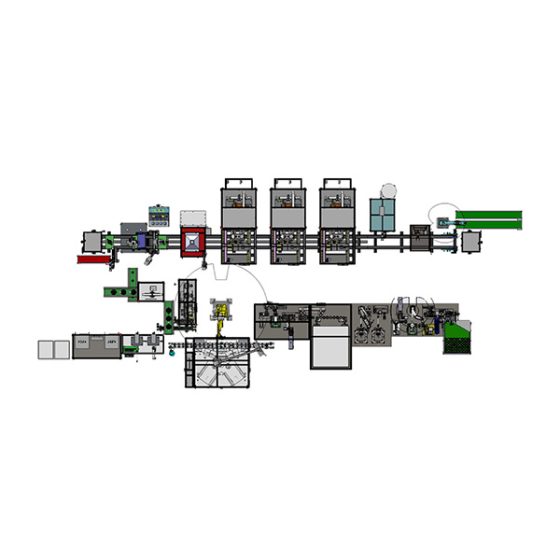

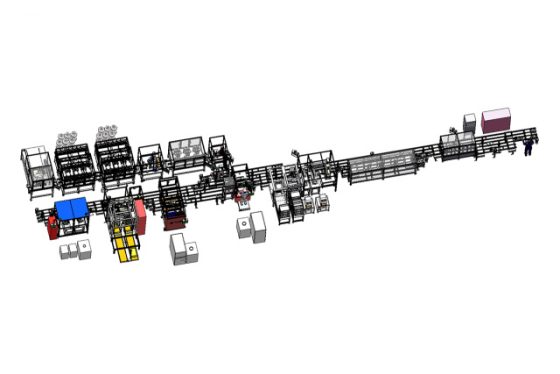

Сборочная линия бесщеточного водяного насоса в основном используется для завершения процесса сборки, отладка, Упаковка и отгрузка компонентов бесщеточных водяных насосов. Сборочная линия обычно хорошо спланирована для реализации производственных целей с высокой эффективностью, Высокое качество и низкая стоимость.

Ключевые слова:

Линия сборки водяных насосов

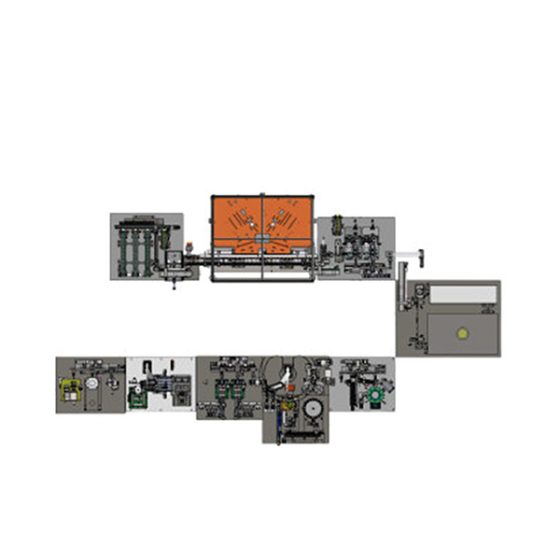

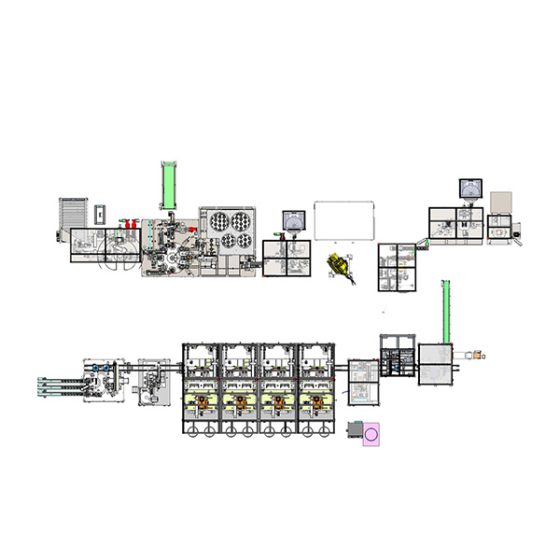

Линия сборки статора ротора водяного насоса

Линия сборки статора ротора водяного насоса

Направление применения: Используется для завершения процесса сборки, отладка, Упаковка и отгрузка компонентов бесщеточного водяного насоса.

Характеристики линейки: Сборочная линия обычно хорошо спланирована для реализации производственных целей с высокой эффективностью, Высокое качество и низкая стоимость.

Линейная структура: Сборочная линия обычно состоит из сборки двигателя, Автоматическое завинчивание, Сборка печатной платы, пайка волной припоя, Горячая клепка или ультразвуковая сварка корпуса, нанесение теплопроводящего силикона, Сборка задней крышки, Сварка задней крышки, Испытание на воздухо- и водонепроницаемость.

Испытание на водонепроницаемость.

Кадровые: 5 операторов на сборочной линии

Преимущества производственной линии: Производственная линия может повысить эффективность производства, снизить производственные затраты, Сокращение ручного вмешательства, и обеспечить качество продукции. Он обладает такими преимуществами, как высокая эффективность, устойчивость, Надежность и высокая степень автоматизации.

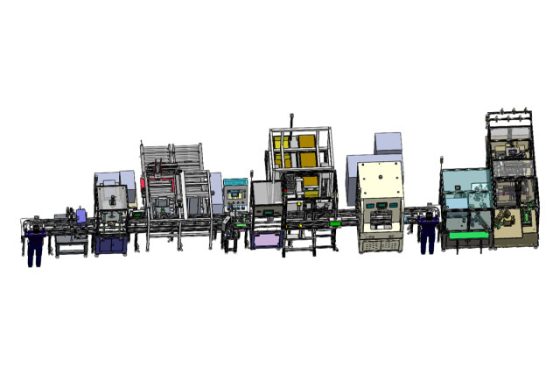

Балансировочные станки JZABM

Балансировочные станки JZABM