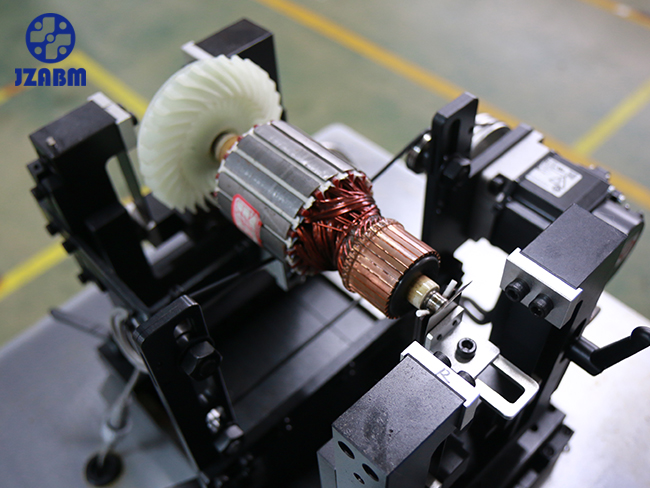

Rotor dynamic balance is an extremely important process in the process of motor manufacturing, which is directly related to whether the noise and vibration performance of the motor meet the standard.

Due to the defects in electrical design of motor, noise and vibration will exceed the standard, which is intertwined with mechanical imbalance, что приводит к чрезвычайно сложным проблемам шума и вибрации двигателя.

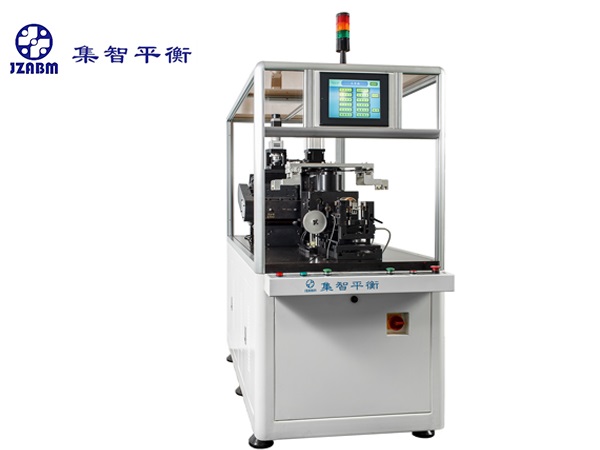

Jizhi has different types of rotor dynamic balancing machines, and their weight removal methods are also different. В то же время, the dynamic balance of the rotor is not a random choice, but the influence on the natural frequency, critical speed and mass should be considered. Weight increase or weight loss, mass change, natural frequency change, so whether to add or lose weight, we should consider the relationship between working speed and natural frequency, and choose the one whose natural frequency is far away from the working speed. Then look at the natural frequency, add 1 gram per kilogram, how much to change the natural frequency.

Due to the rotor in the manufacturing process and assembly process, the final assembled rotor is always unable to achieve complete axial symmetry (called shaft eccentricity), so there is a certain amount of imbalance. This unbalance is usually called the original unbalance.

Балансировочные станки JZABM

Балансировочные станки JZABM