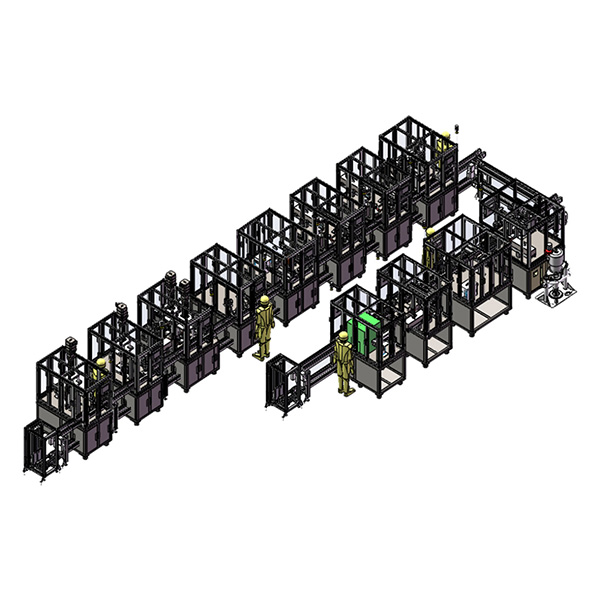

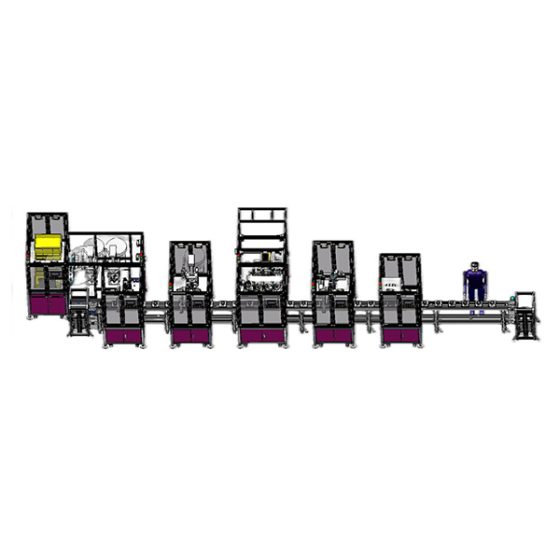

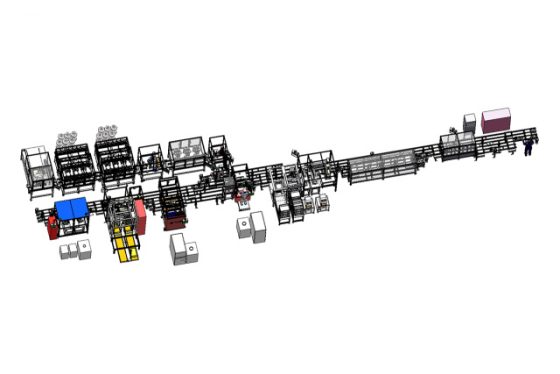

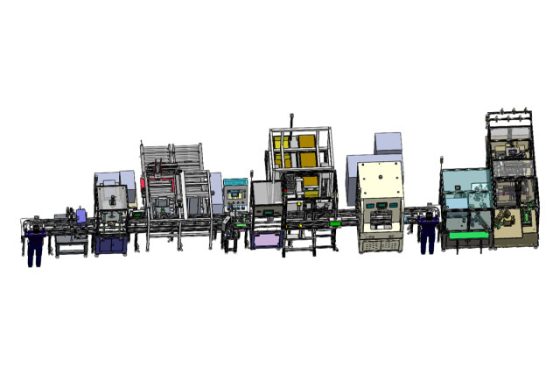

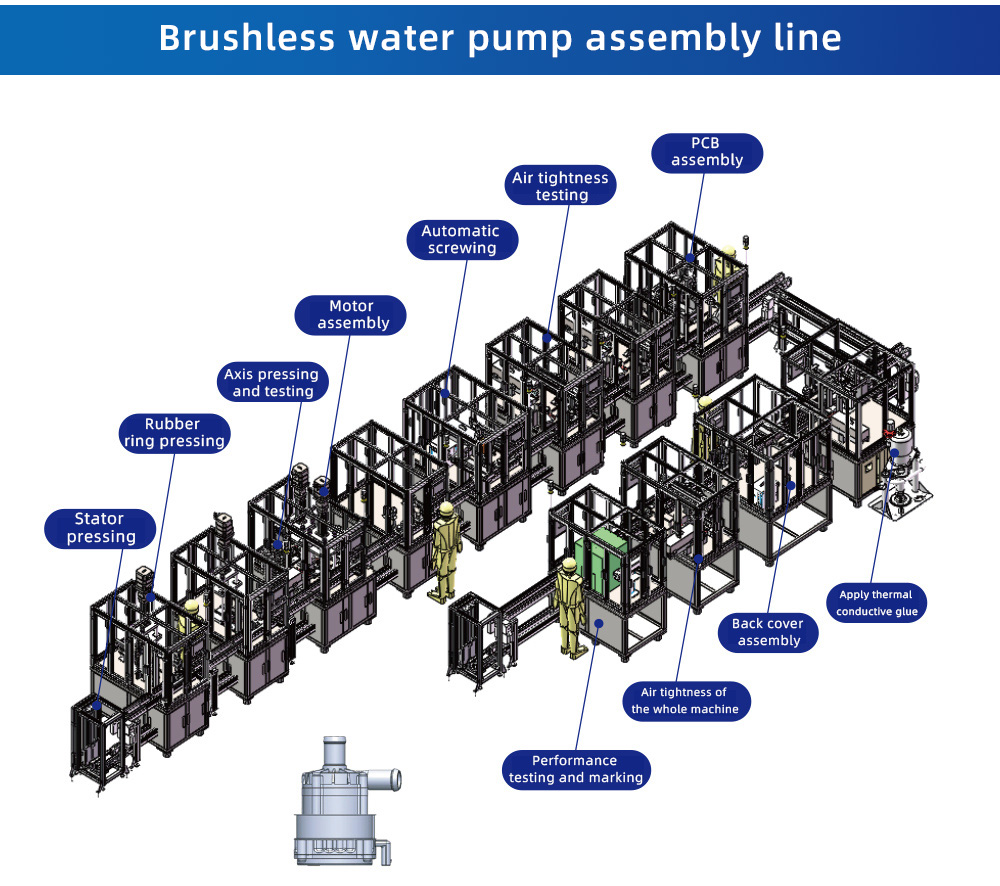

Brushless water pump assembly line is mainly used to complete the process of assembling, debugging, packing and shipping of brushless water pump components. The assembly line is usually well planned to realize the production goals of high efficiency, high quality and low cost.

Palavras-chave:

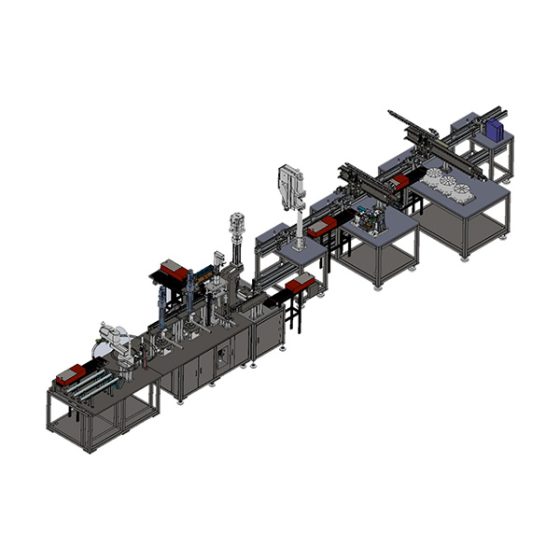

Water pump assembly line

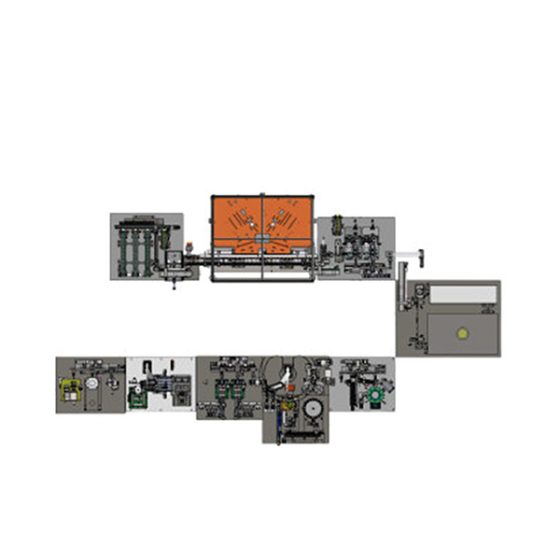

Water pump rotor stator assembly line

Water pump rotor stator assembly line

Application Direction: Used to complete the process of assembling, debugging, packaging and shipping of brushless water pump components.

Line Characteristics: The assembly line is usually well planned to realize the production goals of high efficiency, high quality and low cost.

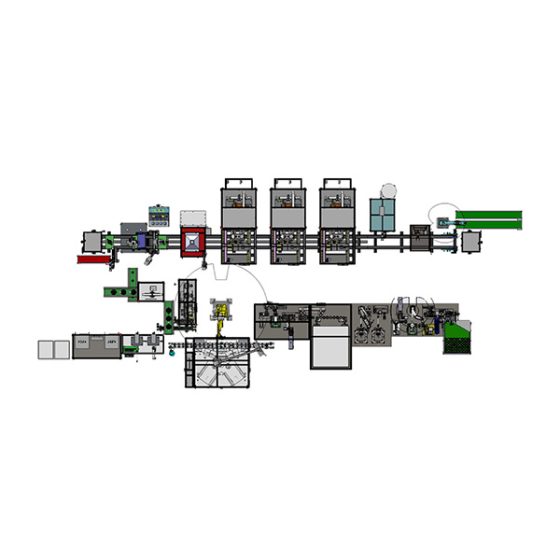

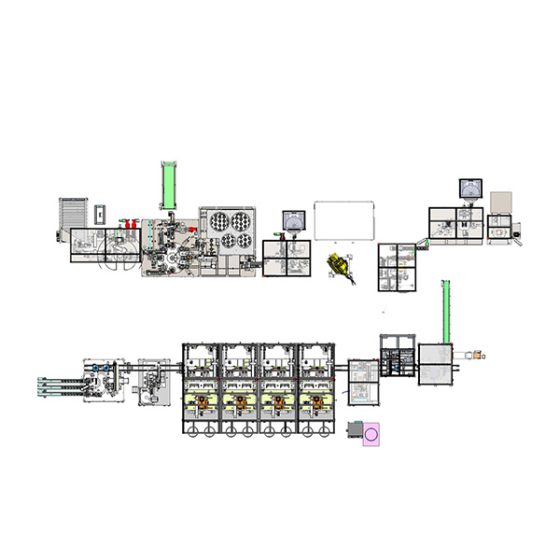

Line structure: The assembly line usually consists of motor assembly, automatic screwing, PCB assembly, wave soldering, hot riveting or ultrasonic welding of the casing, applying thermally conductive silicone, back cover assembly, back cover welding, air and water tightness testing.

water tightness test.

Pessoal: 5 operators in the assembly line

Advantages of the production line: The production line can improve production efficiency, reduce production costs, reduce manual intervention, and ensure product quality. It has the advantages of high efficiency, stability, reliability and high degree of automation.

Máquinas de balanceamento JZABM

Máquinas de balanceamento JZABM