Features:

- The online self-learning function of parameters solves the pain point that depends on the strong

- dependence of manual equipment on people and truly realizes automation and intelligence

- The equipment adopts full plc to control the industrial computer control route which is fouled by the industry to ensure the stability of the equipment control system;

- Aiming at the problem that the straightening accuracy is not up to standard, high-precision sensors and high-precision algorithms are used to achieve the measurement accuracy of 0.001 mm;

- It has multiple functions and can be customized according to customer requirements.

- The customization cycle is short.The system can save a variety of product models and realize one-click tooling change in only 10 minutes;

- With history tracing function and 16G memory card to store processing information and reserve communication interface with upper computer;

- It can be matched with automatic loading and unloading without manual duty.

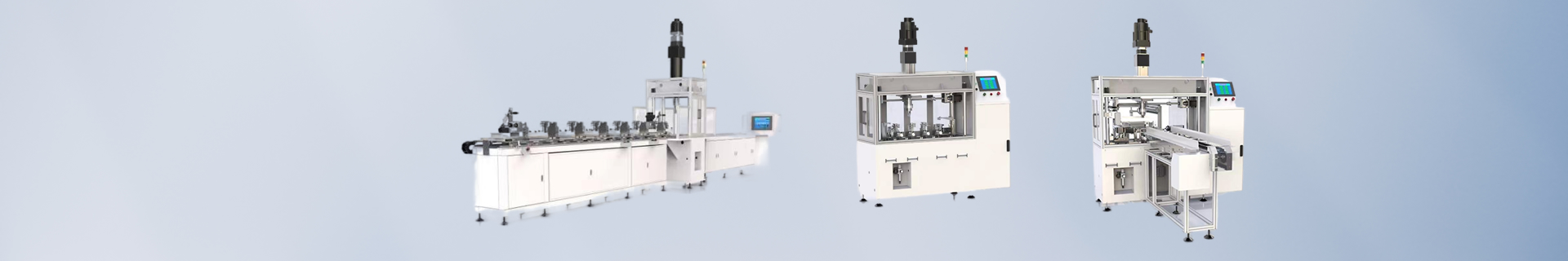

JZABM Balancing Machines

JZABM Balancing Machines