Features:

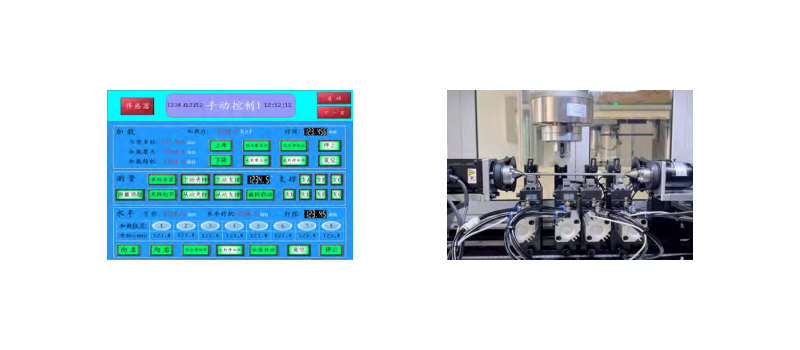

1. Adopting the JZABM intelligent algorithm for automatic detection and intelligent correction of small axis products, achieving fast straightening;

2. Sharply capture the real-time deformation of the current product during a calibration process, achieving a calibration rate of over 90% for the vast majority of products

3. The equipment adopts full PLC control, eliminating the criticized industrial computer control route in the industry, and ensuring the stability of the equipment control system;

4. Adopting high-precision sensors and algorithms to achieve a maximum measurement accuracy of 0.001mm, thereby ensuring measurement accuracy;

5. With historical traceability function, equipped with a 16 GB memory card to store processing information, and reserved communication interface with the upper computer;

6. It has multiple functions and can be customized according to customer requirements, with a short customization cycle;

7. The system can save multiple product models and achieve one click tooling replacement, which only takes 10 minutes;

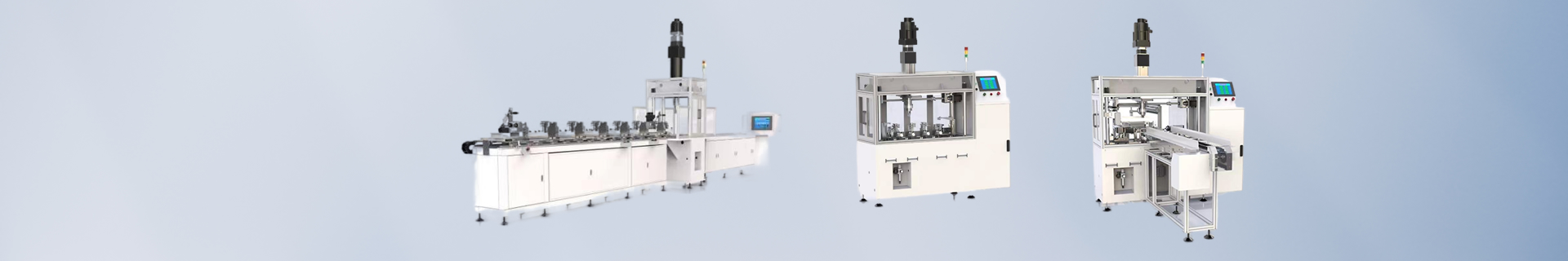

8. It can be paired with fully automatic loading and unloading, without the need for manual monitoring, and comes with a built-in device alarm prompt function, making the operation simple and convenient.

JZABM Balancing Machines

JZABM Balancing Machines