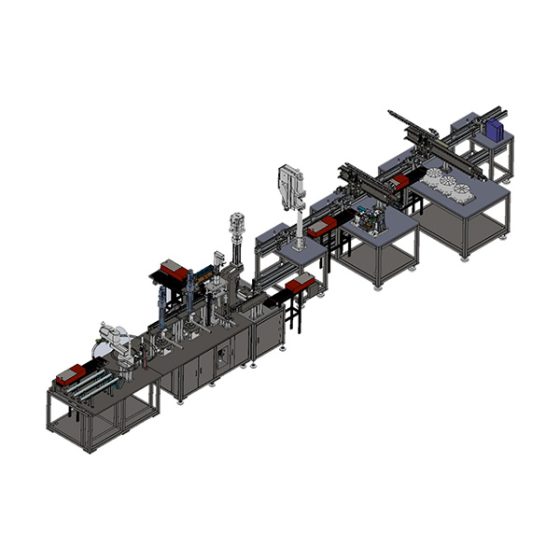

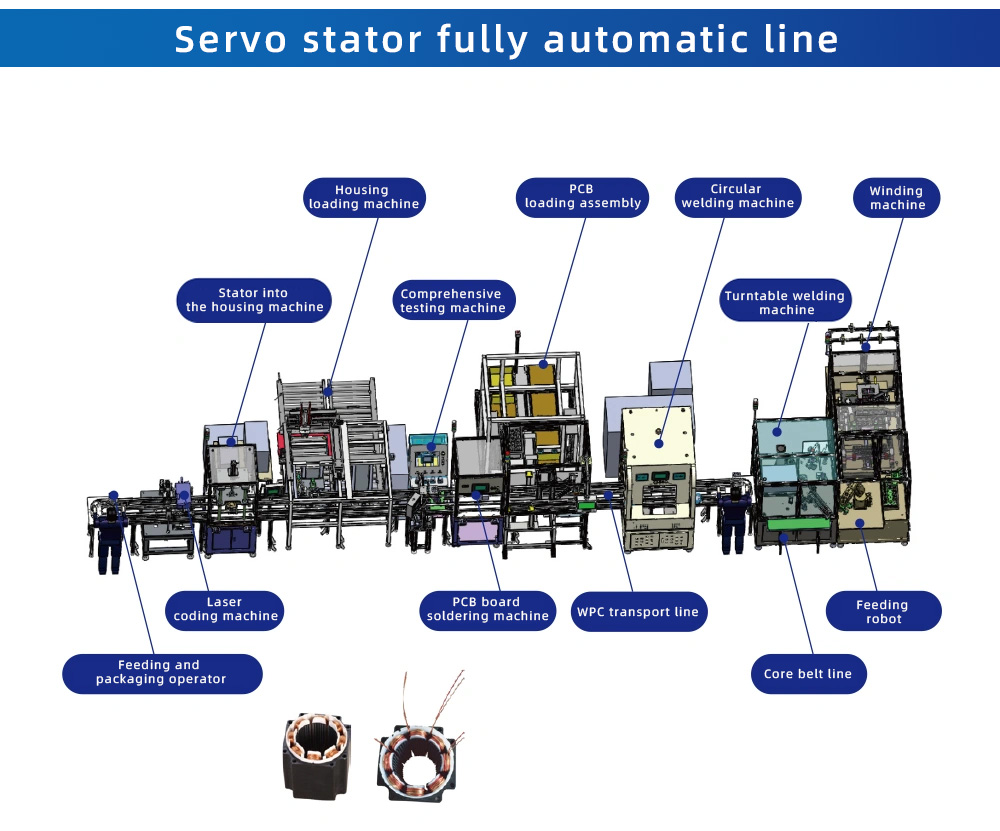

Application Direction: Used for manufacturing stator of servo motor.

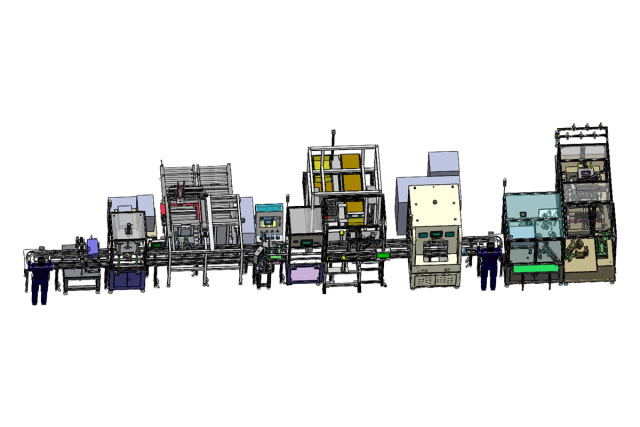

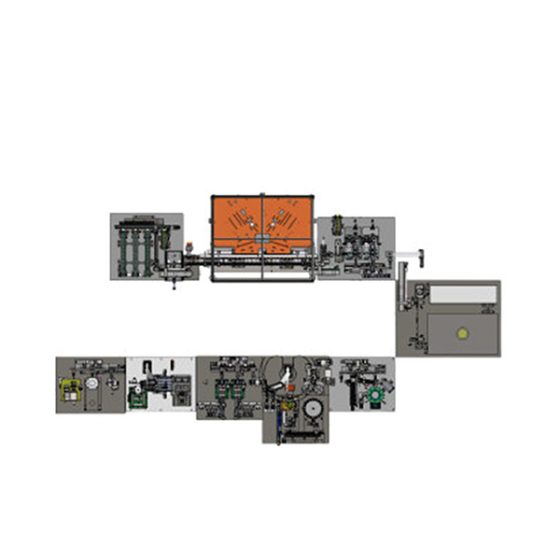

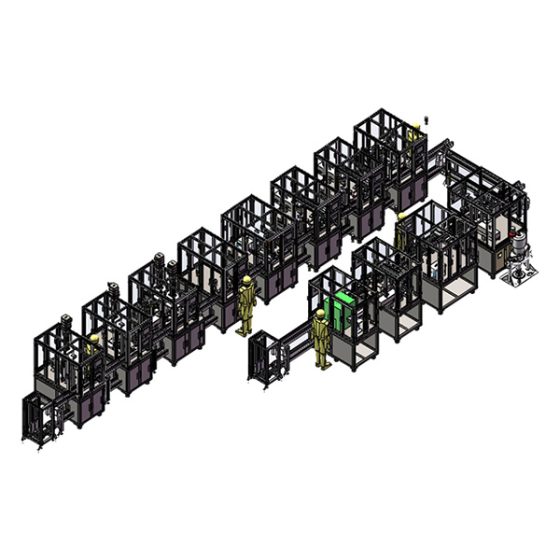

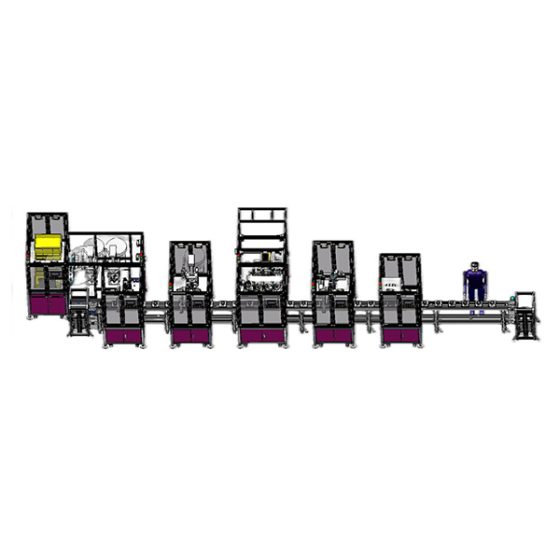

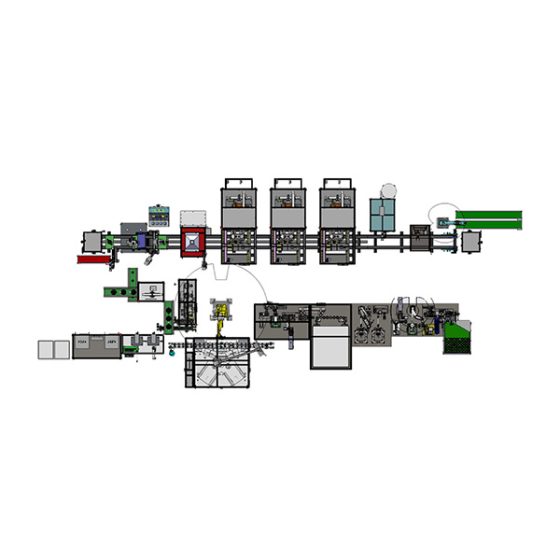

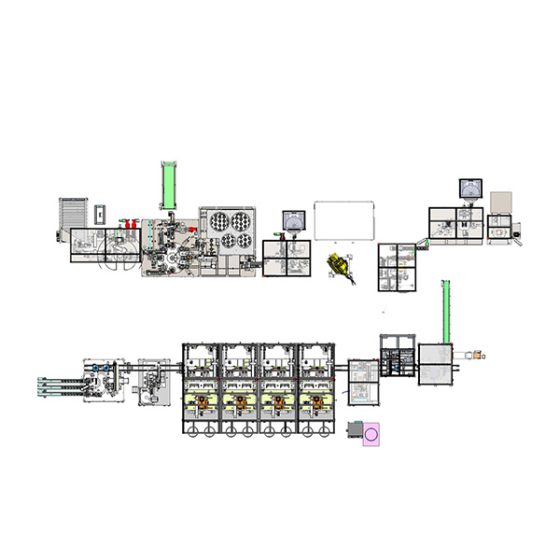

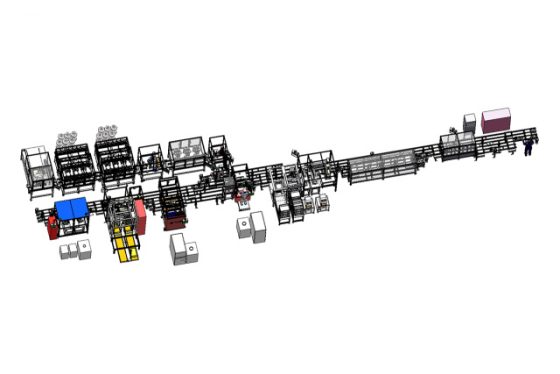

Configuration of production line: This program adopts mechanical structure to convey the stator to connect the various modules of production, with a beat time of ≤60S (can be upgraded to 30S by increasing the number of winding machines and other equipment), equipped with a core loading machine, a stator winding machine, a rotary disc soldering machine, a laser welding machine, a PCB board assembly machine, a motor performance testing machine, a case loading machine, a hot sleeve into the shell machine, a laser Coding machine, a WPC conveyor line.

Staffing: When the stator line is running, it needs to be operated by two people, operator 1 is responsible for finished product appearance inspection, packing and line material replenishment, and operator 2 is responsible for stator block pre-scrambling round. The size of the whole line is about 13270mmx4100mm, and the height of the equipment is 1800mm.

Advantages of the production line: servo stator automatic line production can help manufacturers to improve production efficiency and quality, reduce manual intervention, improve product quality and stability at the same time to achieve efficient automated production.

JZABM Balancing Machines

JZABM Balancing Machines