Fatures:

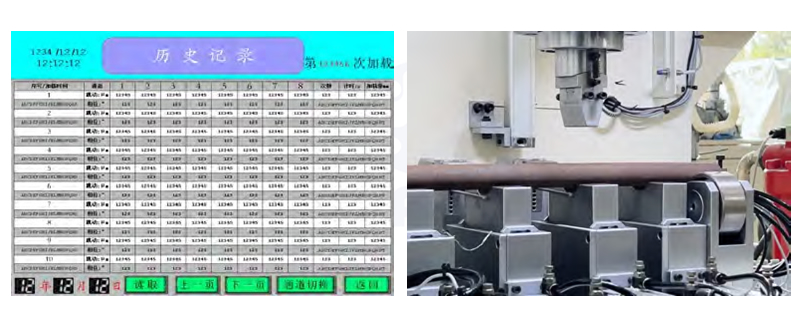

- Equipment testing, tooling, fixtures, etc. are all precisely designed and processed, and high-precision displacement sensors are used to ensure test accuracy;

- During a correction process, the real-time deformation of the current product is captured sensitively, and most products have a correction rate of more than 90%;

- The equipment adopts full PLC control, getting rid of the industrial computer control route criticized by the industry, and ensuring the stability of the equipment control system;

- A control system that can monitor in real time is adopted, and no manual intervention is required during the straightening process;

- It has multiple functions and can be customized according to customer requirements, with a short customization cycle:

- The system can save multiple product models and realize one-click model change, and tooling model change only takes 10 minutes;

- Complete abnormal situation alarm prompt information, convenient equipment maintenance; 8. It can be matched with automatic loading and unloading, without manual supervision.

JZABM Balancing Machines

JZABM Balancing Machines