- Using intelligent algorithm for automatic detection of various rotor products and intelligent correction algorithm to realize fast alignment;

- After setting the basic parameters of the product, the processing and straightening can be carried out without any manual loading parameters, which is truly automatic

- The equipment adopts full plc to control the industrial computer control route which is criticized by the industry to ensure the stability of the equipment control system;

- Using high-precision sensor and high-precision algorithm to achieve the measurement accuracy of 0.001 mm to ensure the accuracy of measurement;

- It has multiple functions and can be customized according to customer requirements. The customization cycle is short:

- The system can save a variety of product models and realize one-click tooling change in only 10 minutes;

- It can be matched with full-automatic loading and unloading without manual duty, and its own equipment prompt function is simple and convenient to operate.

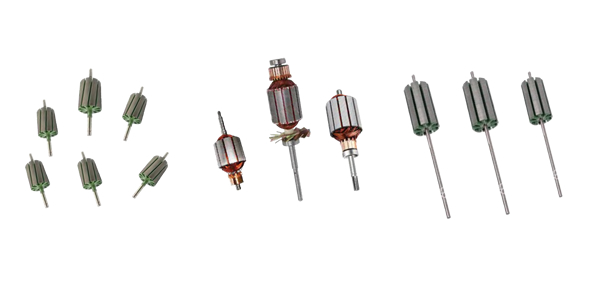

Applicable rotors

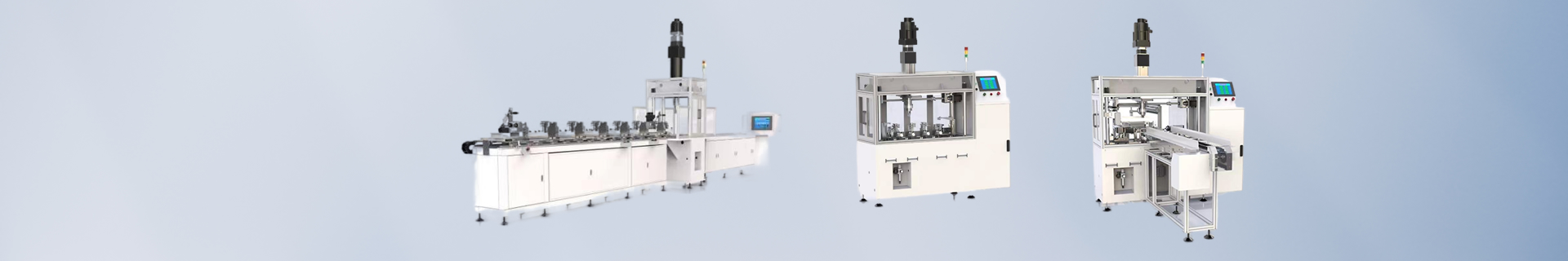

JZABM Balancing Machines

JZABM Balancing Machines