Large screw automatic straightening machine

Features:

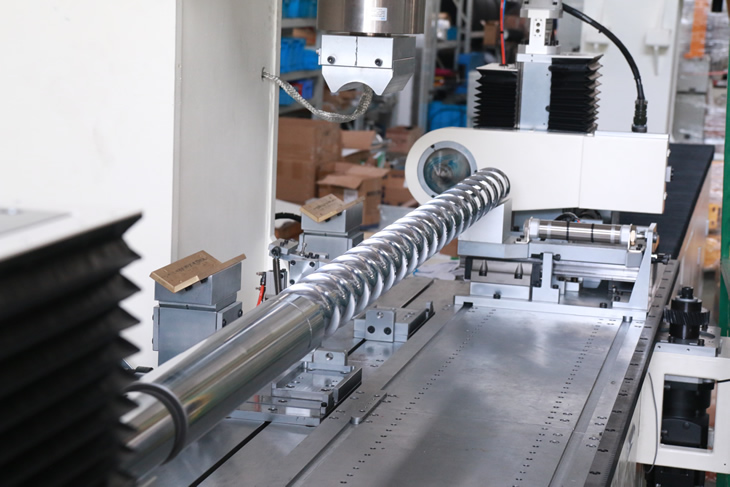

- We independently develop automatic detection and intelligent alignment algorithms for long-axis products to achieve rapid alignment;

- In one correction, the real-time deformation of the current product is keenly captured, achieving a correction rate of more than 90% for most products;

- The equipment adopts full PLC control, and the industrial computer control route has been criticized in the industry to ensure the stability of the equipment control system;

- Use high-precision sensors and high-precision algorithms to achieve a measurement accuracy of 0.001mm, thereby ensuring measurement accuracy;

- With history tracing function, attached 16G memory card to store processing information, and reserved communication interface with the host computer:

- It has a variety of functions and can be customized according to customer requirements, with a short customization cycle;

- The system can save multiple product models and realize one-click model change, and tooling model change only takes 10 minutes.

- Can be equipped with automatic loading and unloading, no manual supervision is required.

It is suitable for radial runout measurement and straightening of steel pipe, screw, long shaft and other products

Q1: How-to vedio provided?

A: Yes. if required, our engineers will record a specialize how-to video for you.

Q2: Are your company a trading one or a factory?

A: As the only listed company in China’s dynamic balancing field, we have two manufacturing plants, one in Shanghai and the other in Hangzhou. 20 years focusing on balancing machines field. 15 years exporting experience, warmly welcome to visit our plant factory.

Q3: After an order is placed, when to deliver?

A: If we have inventory, we can arrange shipment within 7 days. Please be aware that our production lead times depend on specificitems and item quantities.

Q4: What about the after-sales service and product’s quality?

A:After the warranty, the professional after-sale service team will provide perfect technical support.and help customer solve problems encountered while using our product, handies guest problems and complaints professionally and timely. Each instruments must be carried out 100% quality examination and test when shipping and delivery goods. Product use training, each of our product provide video training to show you how to operate. Engineers would be go abroad to training, repair and others help you need.

Q5: what about the packing of equipment?

A: Covered with air bubble film before put the machine into the stanard exporting wooden case, which not only has good shock absorption, impact resistance, heat sso has the advantag- es of nontoxic, odorless, moisture corrosion, good transparency etc.

JZABM Balancing Machines

JZABM Balancing Machines