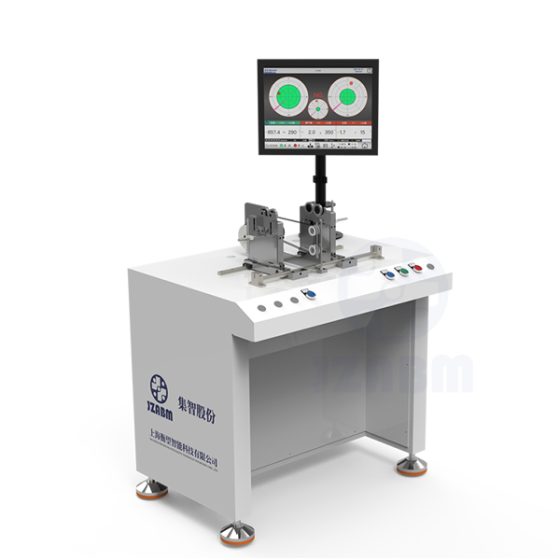

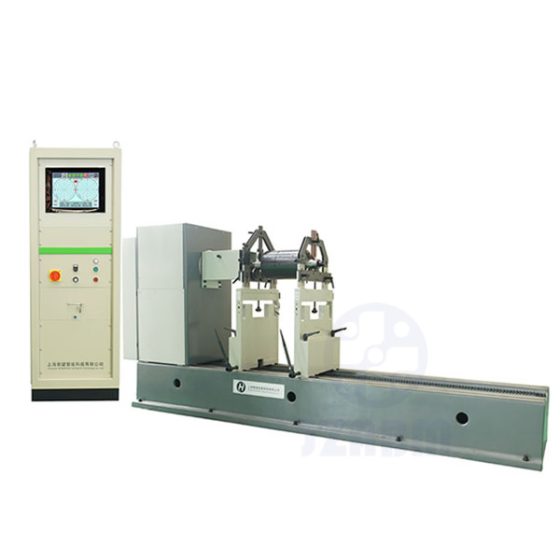

Centrifuge impeller balancing machine are applied to balance detection of various disc-shaped workpieces, such as automobile clutch, brake drum, brake disc, flywheel, fan, fan, impeller of feed pump, etc., which are widely used at present.High precision, high efficiency, easy to operate, intuitive display, good stability, when man-machine dialogue, they have several major characteristics.As long as these series machines are operated by simple calibration program before start-up, they can accurately and quickly display the balance detection of the inspected workpiece after one start-up operation.

These series machines are equipped with various de weight devices, workpiece centering fixtures and dust collection devices according to the needs of users, which can further improve the work efficiency of the balancing machine.

Features:

-

Simple to use software with intuitive unbalance correction displays.

- Each accessory part adopts international and domestic well-known brand products, such as gearboxes, rolling bearings, low-voltage electrical components, etc.

- Strict and complete quality system, complete technology, testing methods and configuration of various metal processing equipment to ensure product quality.

- Perfect comprehensive supporting capabilities, can provide flexible and diverse options, and provide you with the most optimized product configuration.

Clutch Component Balancing Machines 1.Dynamic balancing machines for all industries and rotor types. 2.Manual and automatic dynamic balancing machine solutions for varying production demands. 3.Integrated unbalance correction through drilling, milling, welding etc.

Remark: Based on actual specifications (can be negotiated accroding to customer’s requiement)

Q1: How-to vedio provided?

A: Yes. if required, our engineers will record a specialize how-to video for you.

Q2: Are your company a trading one or a factory?

A: As the only listed company in China’s dynamic balancing field, we have two manufacturing plants, one in Shanghai and the other in Hangzhou. 20 years focusing on balancing machines field. 15 years exporting experience, warmly welcome to visit our plant factory.

Q3: After an order is placed, when to deliver?

A: If we have inventory, we can arrange shipment within 7 days. Please be aware that our production lead times depend on specificitems and item quantities.

Q4: What about the after-sales service and product’s quality?

A:After the warranty, the professional after-sale service team will provide perfect technical support.and help customer solve problems encountered while using our product, handies guest problems and complaints professionally and timely. Each instruments must be carried out 100% quality examination and test when shipping and delivery goods. Product use training, each of our product provide video training to show you how to operate. Engineers would be go abroad to training, repair and others help you need.

Q5: what about the packing of equipment?

A: Covered with air bubble film before put the machine into the stanard exporting wooden case, which not only has good shock absorption, impact resistance, heat sso has the advantag- es of nontoxic, odorless, moisture corrosion, good transparency etc.

JZABM Balancing Machines

JZABM Balancing Machines