Automobile BLDC motor rotor line is mainly used for producing automobile BLDC motor rotors. It meets the needs of automobile manufacturing industry for high efficiency, high quality and high volume rotor production.

Key words:

Automotive BLDC Rotor Wire

Automotive BLDC rotor automatic production line

Application direction: production of automotive BLDC motor rotor

Features: To meet the needs of automobile manufacturing industry for high efficiency, high quality and high volume rotor production.

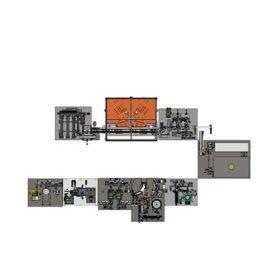

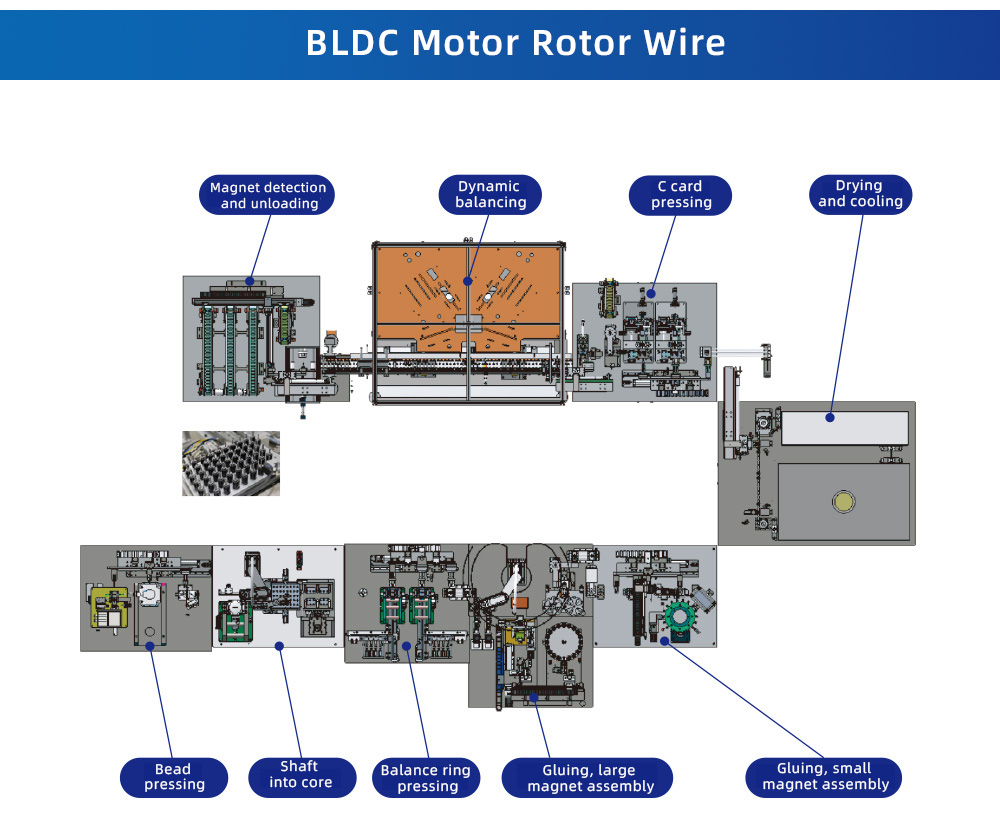

Production line structure: The production line includes: shaft ribbing machine, shaft into the core machine, both sides of the balance ring press, glue, magnetic ring assembly, curing, dynamic balancing, and discharging. It can realize high-precision and high-efficiency production of stator, improve production efficiency and quality stability. It can also reduce the error and labor intensity caused by manual operation, shorten the production cycle and improve the competitiveness of enterprise production.

Advantages of production line: It can greatly improve production efficiency and product quality, and can reduce the possibility of manual error, reduce production costs and shorten the production cycle. At the same time, it can also be adapted to the needs of mass production and improve the automation and intelligence level of the whole production line.

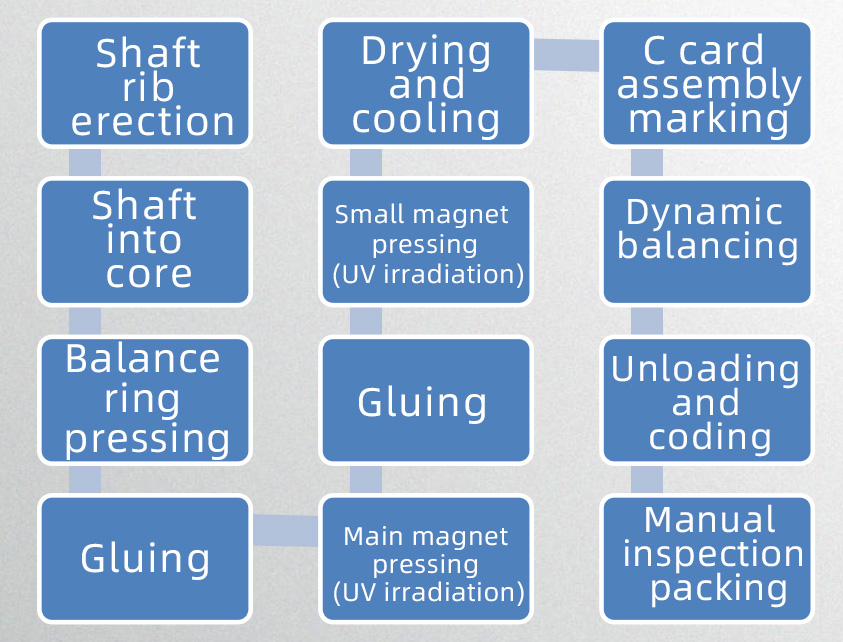

Production process:

Products:

JZABM Balancing Machines

JZABM Balancing Machines