Features:

01

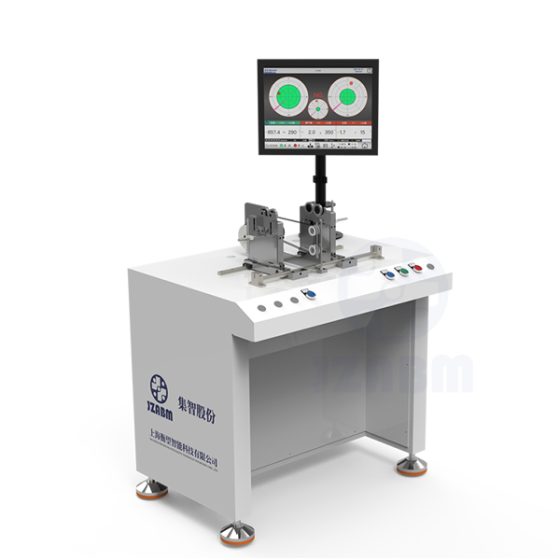

This series of equipment is a special equipment for correcting the imbalance of the drive shaft of the car, which can correct the imbalance of the two drive shafts at the same time. The positioning lock or release after the movement of the middle and right support frames and the lifting and lowering of the safety frame lever are pneumatically controlled. The machine has advanced technology, high efficiency, simple operation, intuitive display, rapid measurement and good stability.;

02

The equipment of this series can be correctly adjusted according to the radius of the two calibration faces of the rotor before starting, and the unbalance amount and phase of the workpiece can be correctly displayed under one start. The HW310 new generation special electrical measurement system matched with this machine is based on the PLC platform. The measurement is stable, the function is complete, the touch screen operation is possible, and the human-machine dialogue function is powerful;

03

This series of equipment can be equipped with a projection welding machine to meet the welding of the balance plate and the shaft tube when the drive shaft is calibrated, reducing the operator’s working load and improving production efficiency. The balancing machine and the projection welding machine have interlock protection devices. The projection welding machine adopts microcomputer control, with large parameter setting range, high control precision, stable performance and compensation function for the power grid;

Two-section drive shaft balancing machine workpiece

Three-section drive shaft balancing machine workpiece

JZABM Balancing Machines

JZABM Balancing Machines