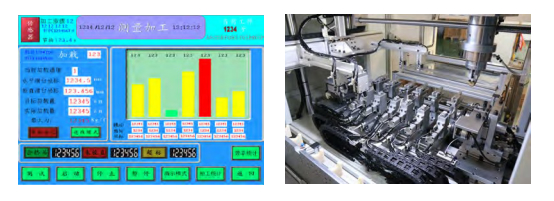

1. The device has a fully automatic changeover function, which can switch between mechanical position and workpiece parameters with just one click;

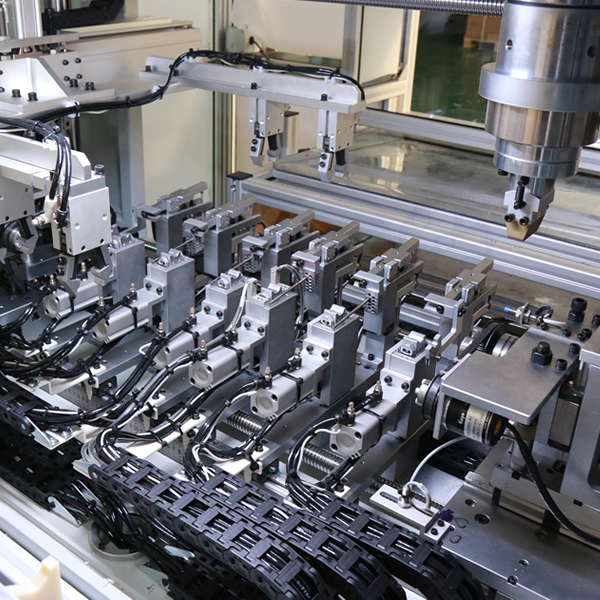

2. Equipment testing, tooling, fixtures, etc. are all precision designed and processed;

3. The equipment uses high-precision testing sensors to achieve stable measurement and accurate positioning;

4. The equipment adopts full PLC control, eliminating the criticized industrial computer control route in the industry, and ensuring the stability of the equipment control system;

5. Reduce the requirements for equipment usage environment and be able to adapt to various environments from zero to extreme heat;

6. It has multiple functions and can be customized according to customer requirements, with a short customization cycle;

7. The system can save multiple product models and achieve one click tooling replacement, which only takes 10 minutes;

8. With historical traceability function, equipped with a 16 GB memory card to store processing information, and reserved communication interface with the upper computer;

Fully automatic type changing and straightening machine

pic of automatic type changing and straightening machine

JZABM Balancing Machines

JZABM Balancing Machines