핵심어:

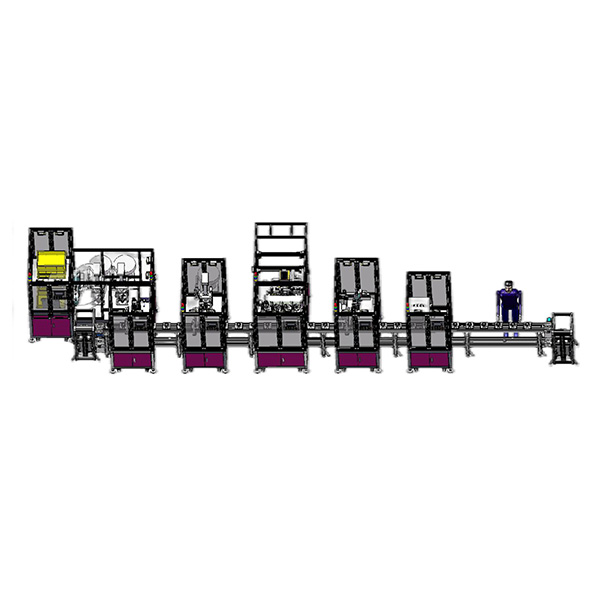

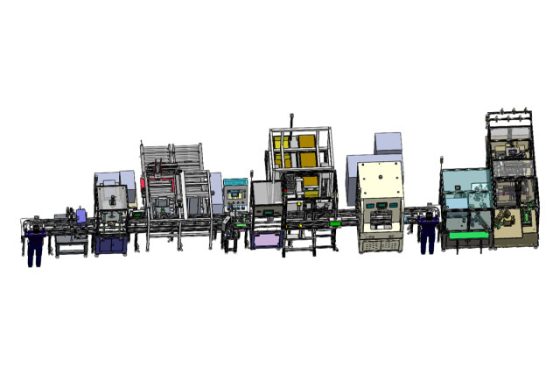

워터 펌프 고정자 자동 생산 라인

워터 펌프 고정자 생산 라인

워터 펌프 모터 고정자 생산 라인

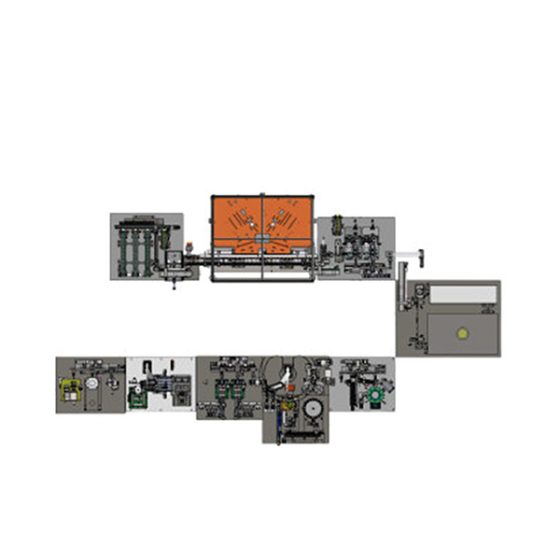

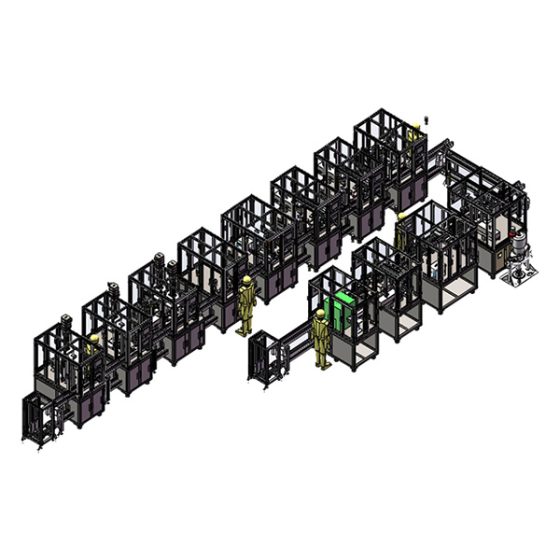

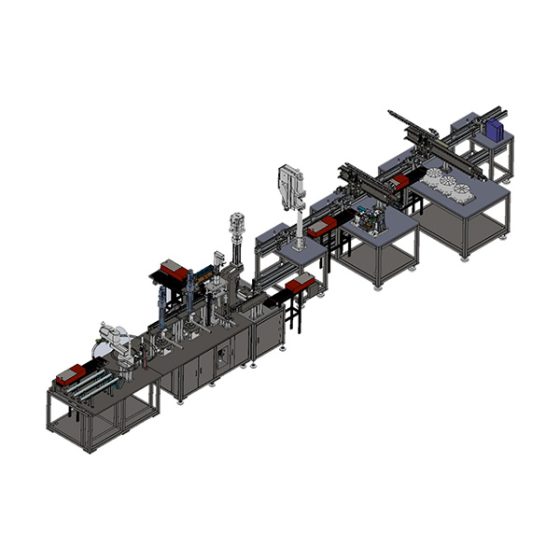

1.고정자 코어 로딩 시스템: 처리된 고정자 코어를 컨베이어 벨트 또는 다른 수단을 통해 고정자 조립 영역으로 전달합니다.;

2.엔드 플레이트 조립 시스템: 고정자의 양쪽에 엔드 플레이트를 고정자에 순서대로 설치하십시오.;

3.고정자 피닝: 진동 디스크 로딩을 통해 조립 영역에 연결 단자를 제공하십시오., 그리고 핀을 위해 로봇으로 재료를 집어 듭니다.. 삽입 고도를 시험하십시오 4.after 삽입;

5.고정자 권선: 감기 과정에 따라 감기;

6.단자 스폿 용접: 단자와 구리선을 저항 용접으로 용접합니다.;

7.감지 시스템: 조립된 고정자에 대해 여러 가지 전기 성능 테스트를 수행하여 고정자의 성능 지수가 필요한 표준을 충족하는지 확인합니다.;

8.포장 시스템: 자격을 갖춘 펌프 고정자는 재료 아래에 포장되어 있습니다..

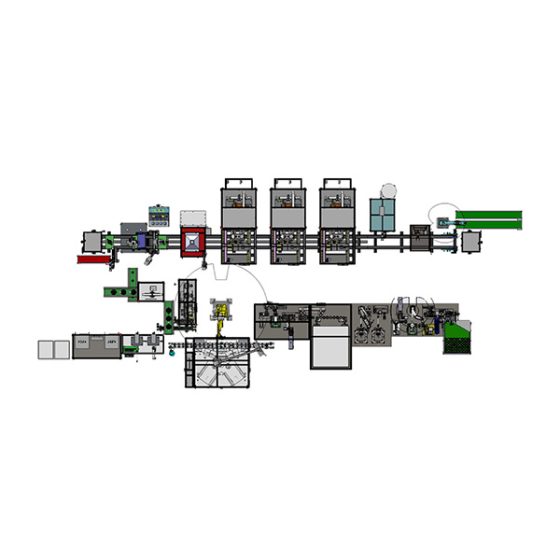

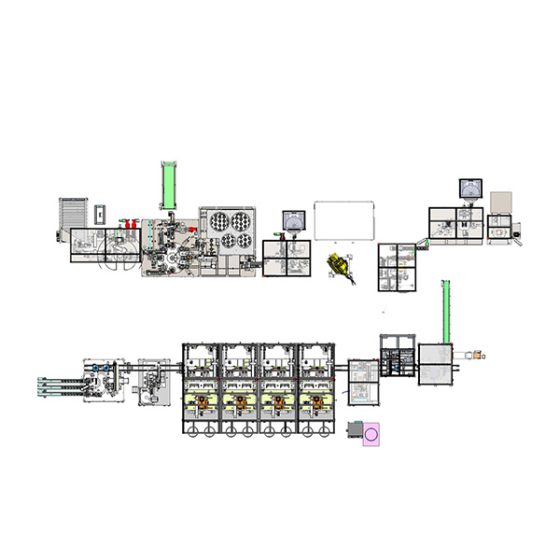

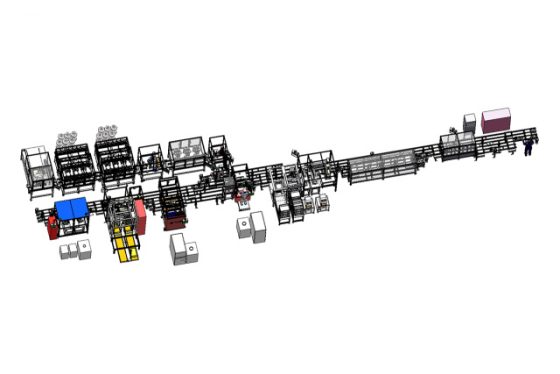

생산 과정:

- 고정자 코어 하중 → 고정자 육안 검사 → 상부 및 하부 플레이트 어셈블리 → 레이저 코딩 → 인서트 프레스 피팅 → 인서트 검사 → 로봇 고정자 로딩 → 고정자 권선 → 인서트 용접 →상 링 어셈블리 → 전기 성능 테스트 → 수동 방전

JZABM 밸런싱 머신

JZABM 밸런싱 머신