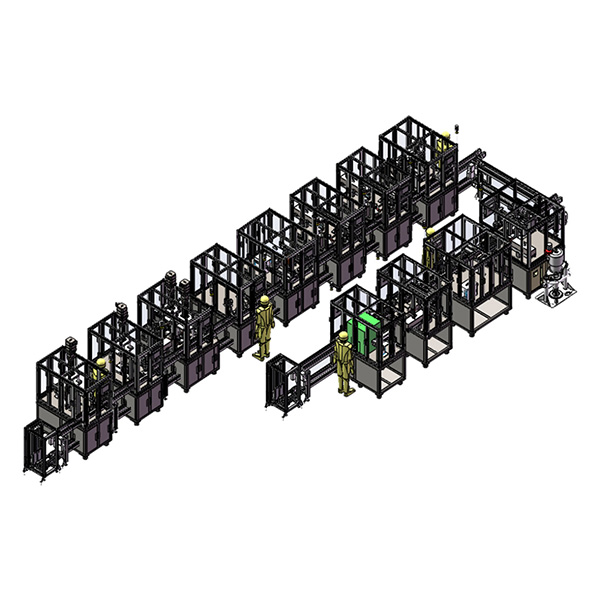

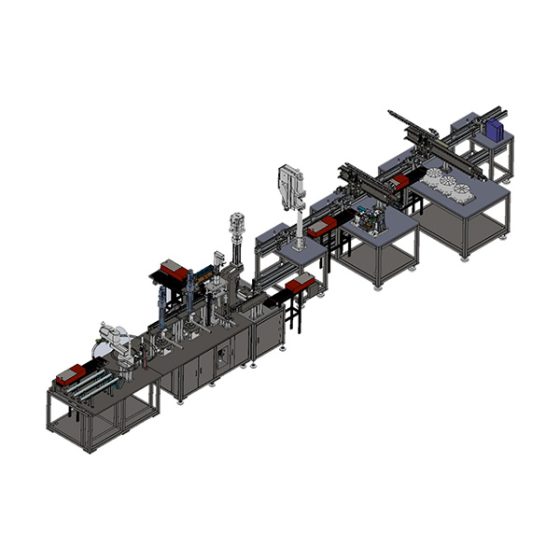

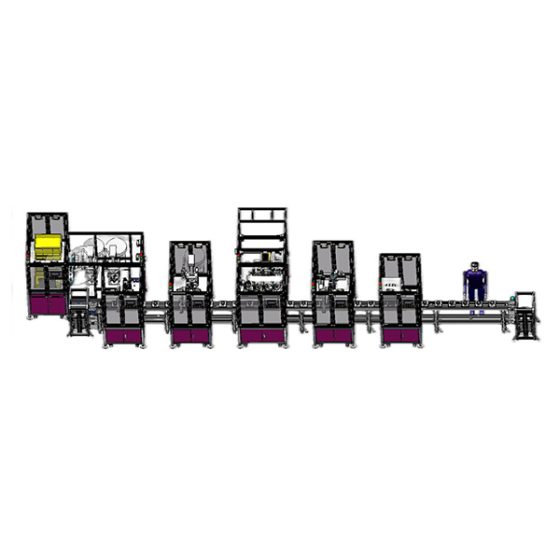

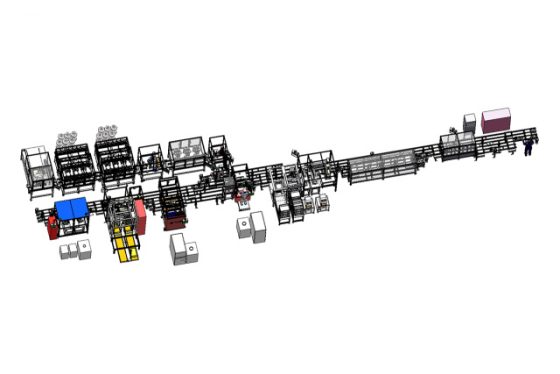

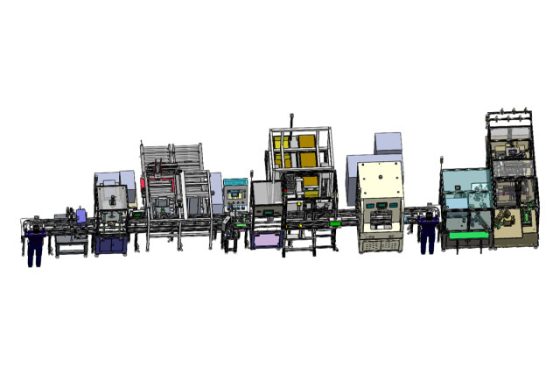

Brushless water pump assembly line is mainly used to complete the process of assembling, debugging, packing and shipping of brushless water pump components. The assembly line is usually well planned to realize the production goals of high efficiency, high quality and low cost.

핵심어:

Water pump assembly line

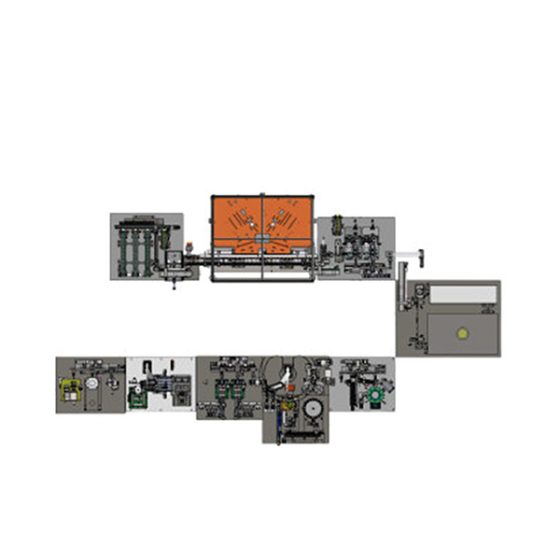

Water pump rotor stator assembly line

Water pump rotor stator assembly line

응용 프로그램 방향: Used to complete the process of assembling, debugging, packaging and shipping of brushless water pump components.

Line Characteristics: The assembly line is usually well planned to realize the production goals of high efficiency, high quality and low cost.

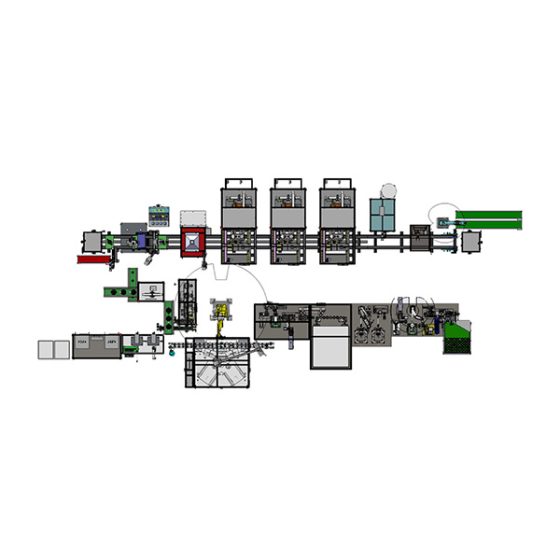

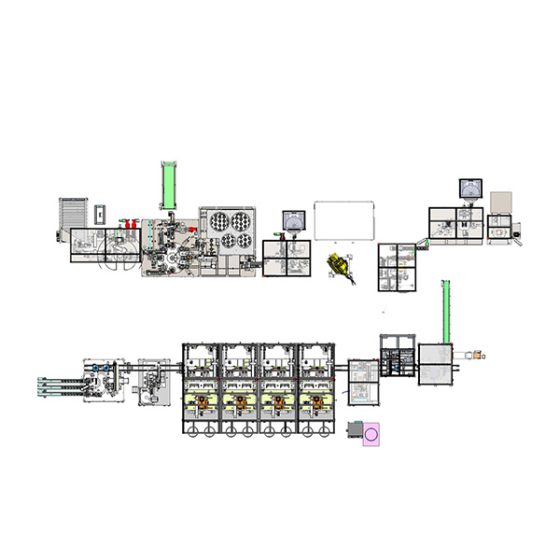

Line structure: The assembly line usually consists of motor assembly, automatic screwing, PCB assembly, wave soldering, hot riveting or ultrasonic welding of the casing, applying thermally conductive silicone, back cover assembly, back cover welding, air and water tightness testing.

water tightness test.

인력: 5 operators in the assembly line

생산 라인의 장점: The production line can improve production efficiency, 생산 비용 절감, 수동 개입 감소, 제품 품질을 보장합니다.. 그것에는 고능률의 이점이 있습니다, 착실, reliability and high degree of automation.

JZABM 밸런싱 머신

JZABM 밸런싱 머신