자동차 브레이크 디스크 다이나믹 밸런싱 머신, 밀링으로 무게를 제거하기 위해 수직 단일 평면!

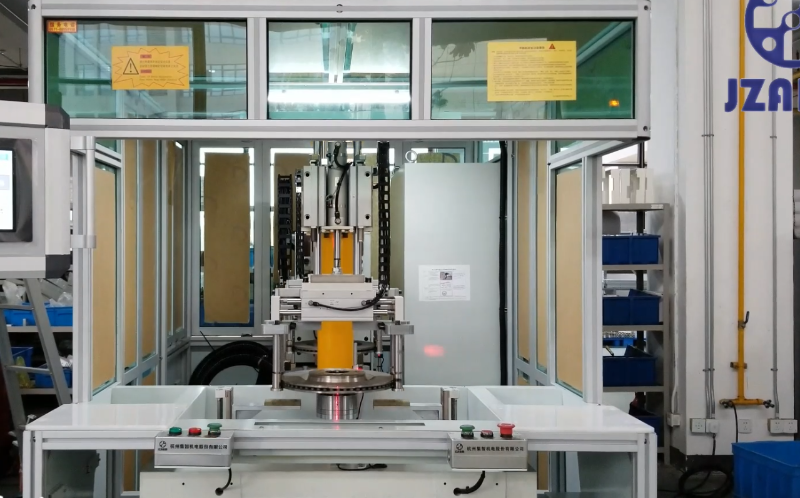

Jizhi 2 스테이션 브레이크 디스크 동적 밸런싱 기계는 단일 기계로 공작물의 균형을 자동으로 조정할 수 있습니다., 또는 생산 라인에 연결하면 완전히 자동화할 수 있습니다., and can be equipped with MES system to achieve data traceability; Characteristics of balanced weight removal: milling area is limited (avoiding process hole, milling circumferential discontinuity, limiting 180 degree area, 등.) or not limited (no requirements for area), and milling position (radius, plane) and allowable milling depth are specified arbitrarily.

The two station brake disc dynamic balancing machine can test the unbalance of the workpiece, automatically carry and remove weights, and retest the residual unbalance of the workpiece to make the workpiece reach the balance result. 테스트의 전 과정, removing weights and retesting does not require manual participation. The brake disc dynamic balancer is mainly divided into three modules: test station, manipulator and cutting. The functions and configurations of each module are as follows:

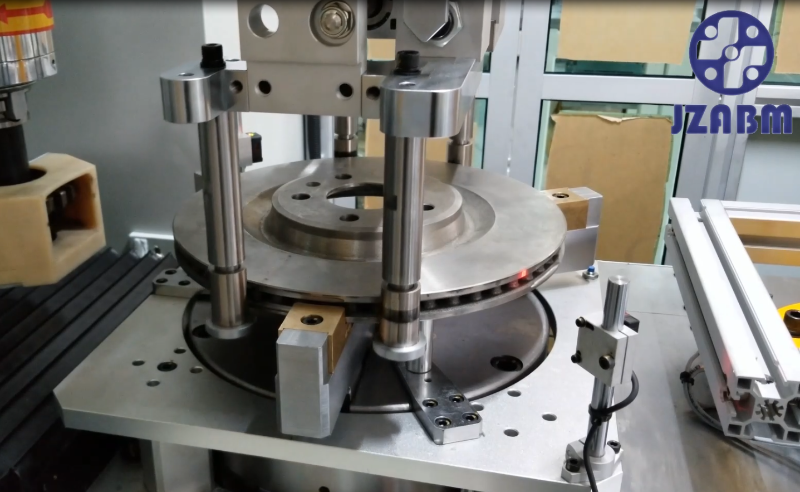

1. Cutting station function: the workpiece with initial unbalance measured is milled to remove weight to make it meet the expected requirements;

Corresponding configuration: cutting turntable, horizontal sliding table, cutting spindle;

2. Manipulator function: exchange the workpiece of cutting parts and testing parts to make the machine run continuously and stably;

Corresponding configuration: divider, claw clamp cylinder, 서보 모터;

3. Test station function: test the unbalance of the workpiece, stop at the position where the weight needs to be removed, and display the result on the display screen;

Corresponding configuration: 서보 모터, test spindle, expansion sleeve, test sensor;

The measuring station of the Two station brake disc dynamic balancing machine has the function of both initial measurement and re measurement, which is used to measure the initial unbalance of the rotor as the basis for weight removal. After the test, it is positioned to align the cutting position with the tool; After the weight removal, measure the residual unbalance to determine whether the workpiece is qualified. The testing station is a vertical one-sided balance testing machine. The workpiece is fixed on the measuring spindle by a pneumatic expanding fixture. The AC servo motor drives the spindle to rotate. The high-sensitivity dynamic coil sensor detects the vibration and then calculates the unbalance.

JZABM 밸런싱 머신

JZABM 밸런싱 머신