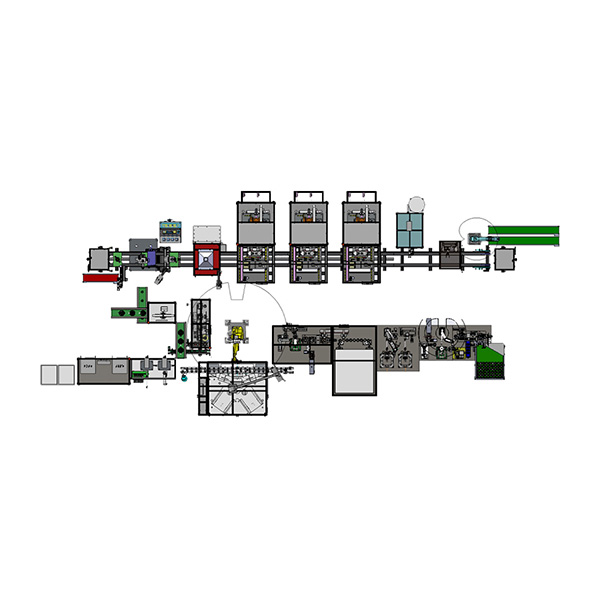

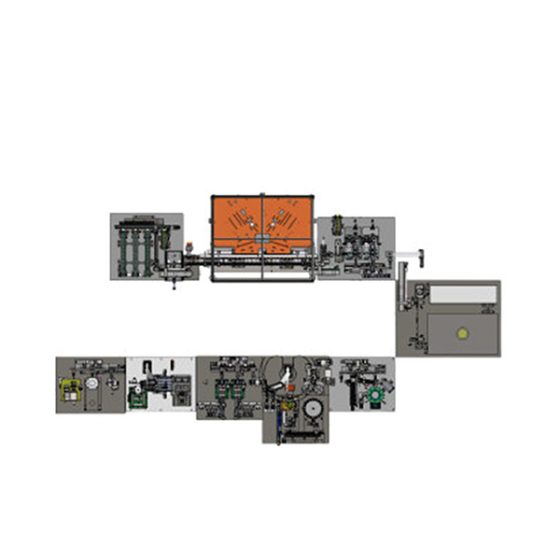

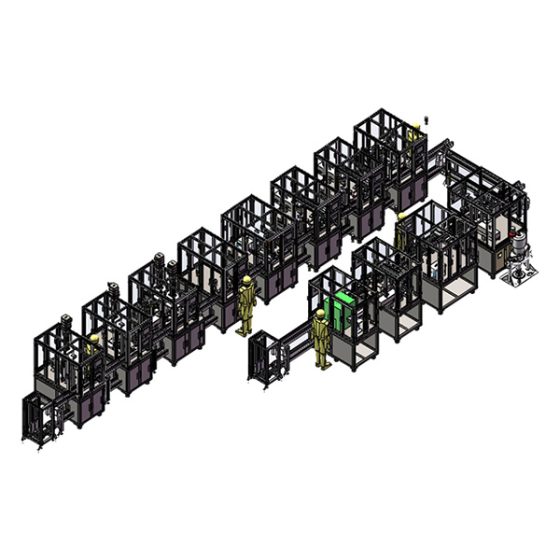

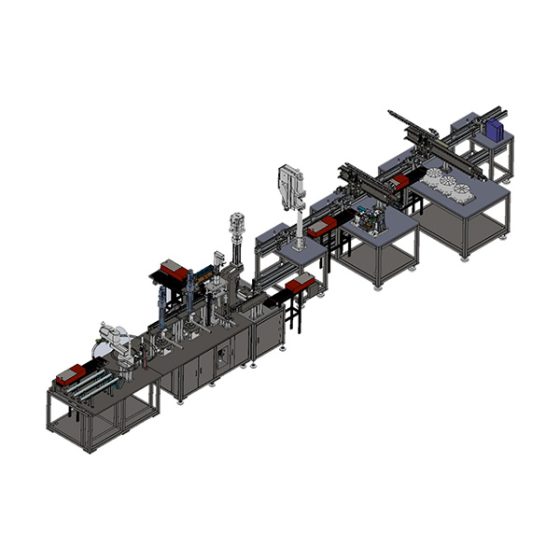

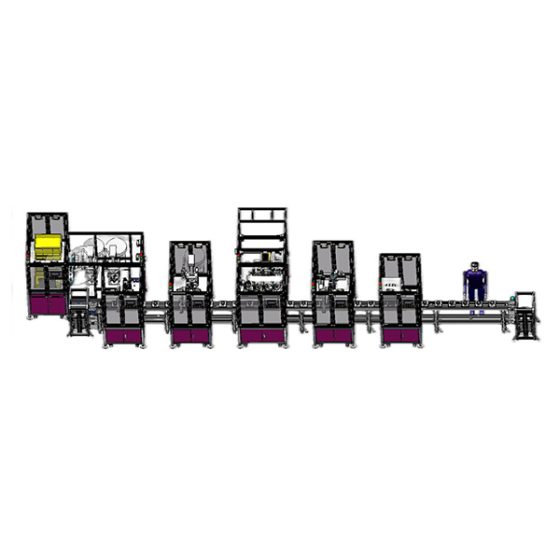

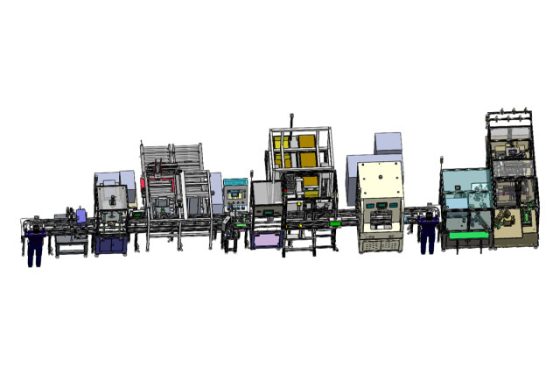

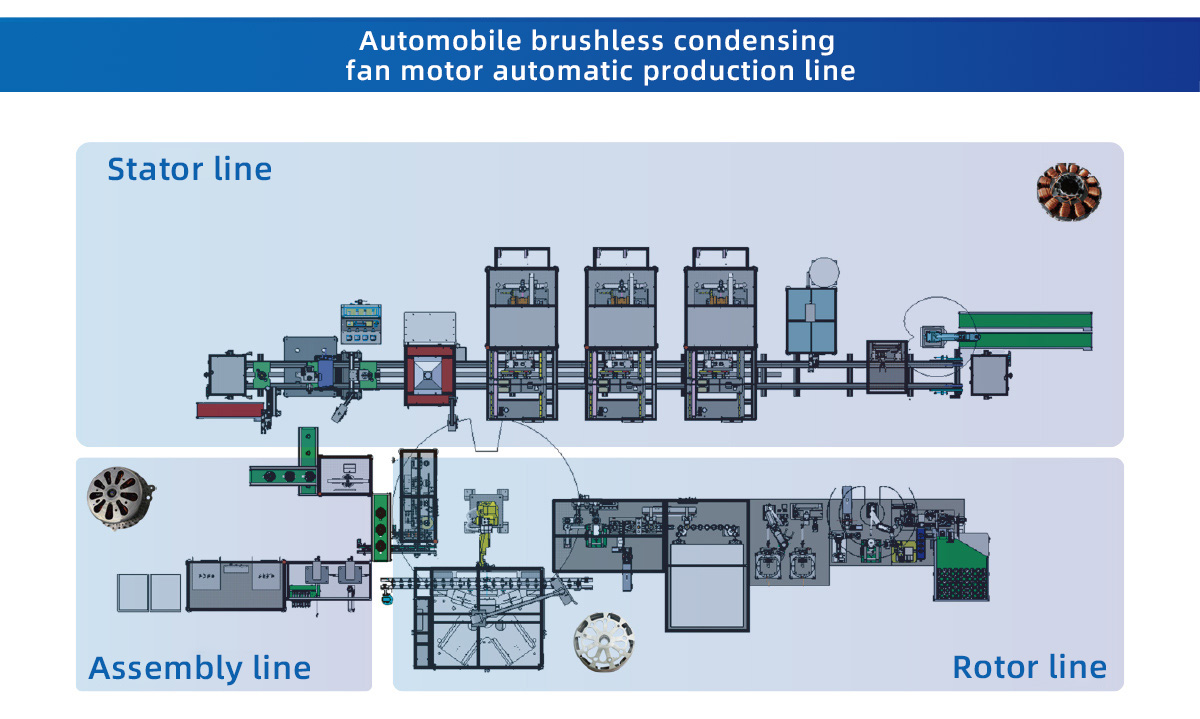

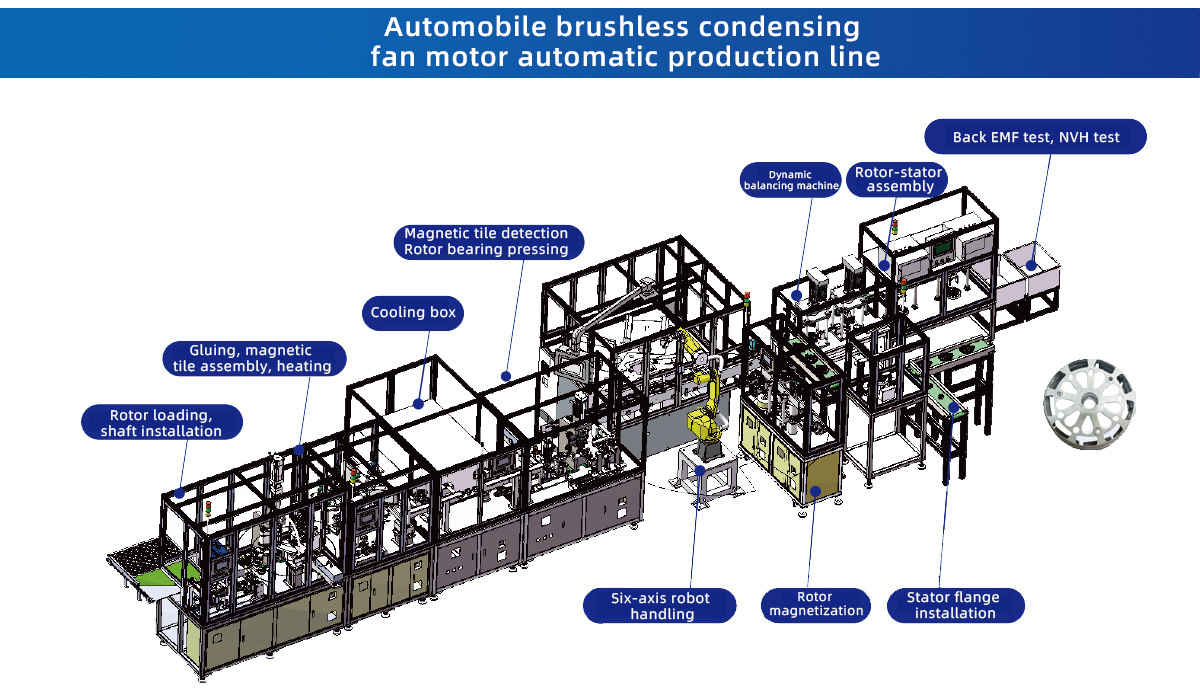

Automotive brushless cooling fan motor automatic production line mainly includes stator loading, pin insertion, winding, electrical testing, rotor loading, gluing into the tiles, curing, cooling, pressing bearings and spacer rings, loading circlips, dynamic balancing, assembling, no-load as well as load testing, 等。, which can reduce the possibility of manual error, 生産コストの削減, improve production efficiency and enhance the image of the enterprise.

- Mainly used in the production of automotive condensing fan brushless motors

- It mainly includes stator loading, pin insertion, winding, electrical testing, rotor loading, gluing into tiles, curing, cooling, pressing bearings and spacers, mounting of circlips, dynamic balancing, assembly, no-load as well as load testing, 等。, which realizes a highly efficient and high-quality production process.

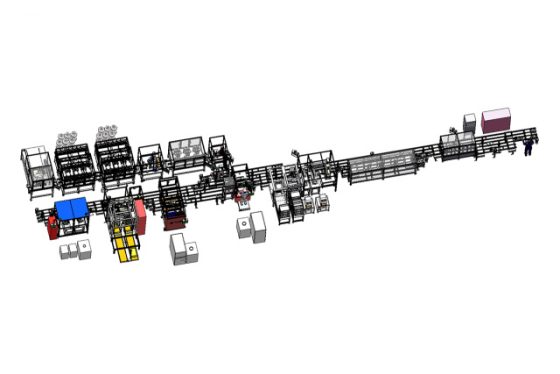

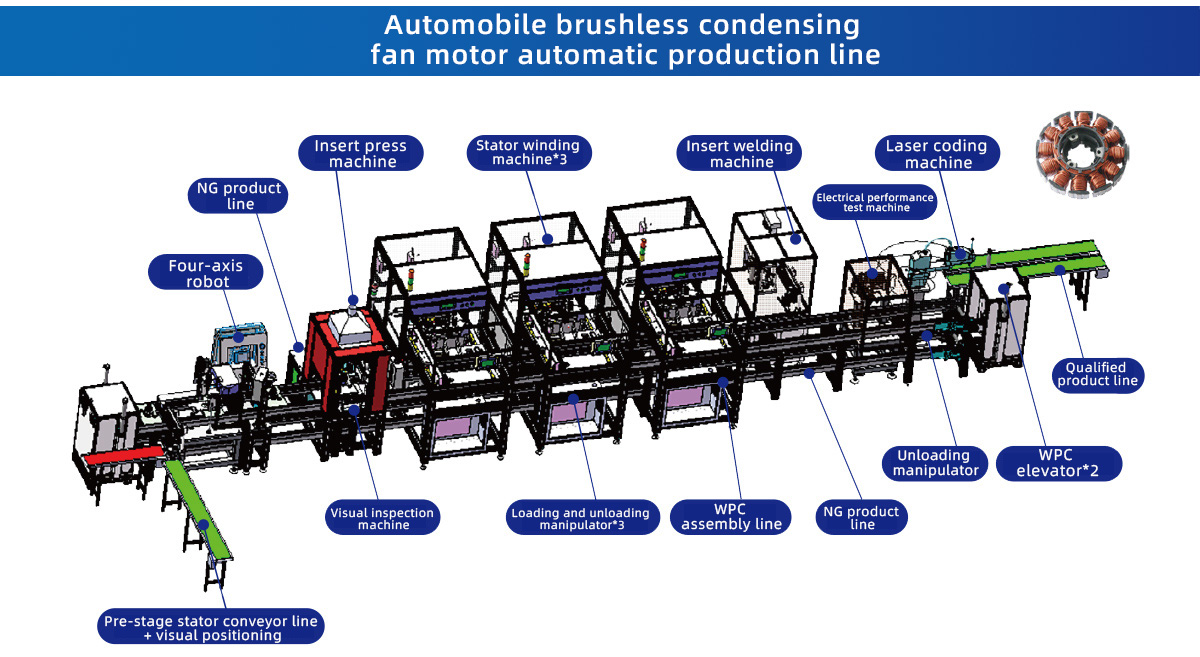

1.Robot operation can realize a variety of complex actions, the use of automatic control systems can effectively improve production efficiency, reduce labor costs, ensure product quality, but also timely quality traceability and continuous improvement.

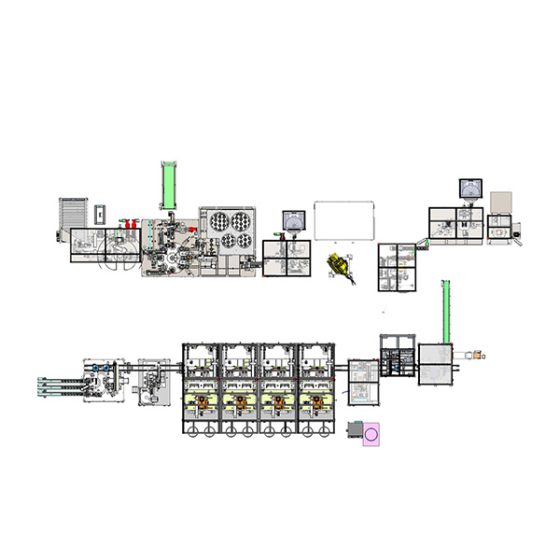

2.The production line usually adopts PLC automatic control technology and utilizes sensors, vision and other monitoring and feedback equipment to ensure the stability and reliability of the production process.

3.The production line is equipped with automated testing equipment, visualization management software, 等。, which makes the operation convenient, 生産管理プロセスを簡素化, realizes the fine degree of control over the production process, and improves the production efficiency and product quality.

生産プロセス:

- Stator core loading → stator visual inspection → upper and lower end plate assembly → laser coding → insert press fitting → insert inspection → robotic stator loading → stator winding → insert welding → phase ring assembly → electrical performance test → manual discharging

JZABMバランシングマシン

JZABMバランシングマシン