Common Questions in Balancing Machine

- The data is large and the angle is large.

Check as follows: Check that the speed is normal and check the belt for wear.

- Detection was unsuccessful

There are generally two reasons for the unsuccessful detection.

The first is that the speed is unsuccessful, the speed is not enough, the stall is blocked, the belt is slipping, the speed ratio parameter setting is incorrect, the slot sensor is damaged or the iron scrap is stuck, この現象を引き起こす可能性があります.

The second is that the number of measurements exceeds the allowed number of times. Generally caused by the vibration data jittering super-permissible jitter value. Check for foreign objects on the rotor shaft to determine if the sensor is worn.

- More sampling times

Check for oil on the belt. The wrap angle is too large and the belt is too loose. Check for any foreign objects on the rotor shaft.

- High speed jump

Check if the driven wheel is flexible, check if the belt is cracked, and check if the felt pad is worn.

- Belt replacement

In the case of cracks, when it is too loose to adjust, when there is oil on the top, the belt can be replaced when the rotation speed is unstable.

- Automatic tool setting point is always bright

There are two reasons for the automatic tool setting point: one is mechanical failure, and the other is circuit failure.

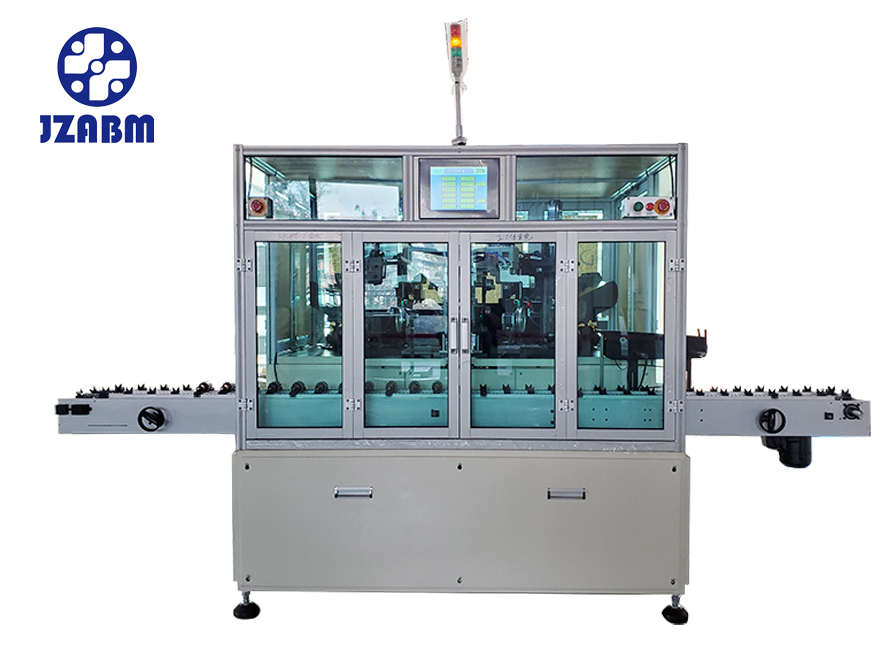

JZABMバランシングマシン

JZABMバランシングマシン