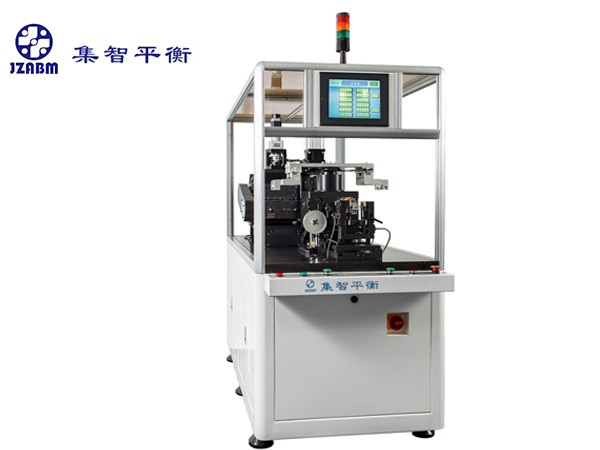

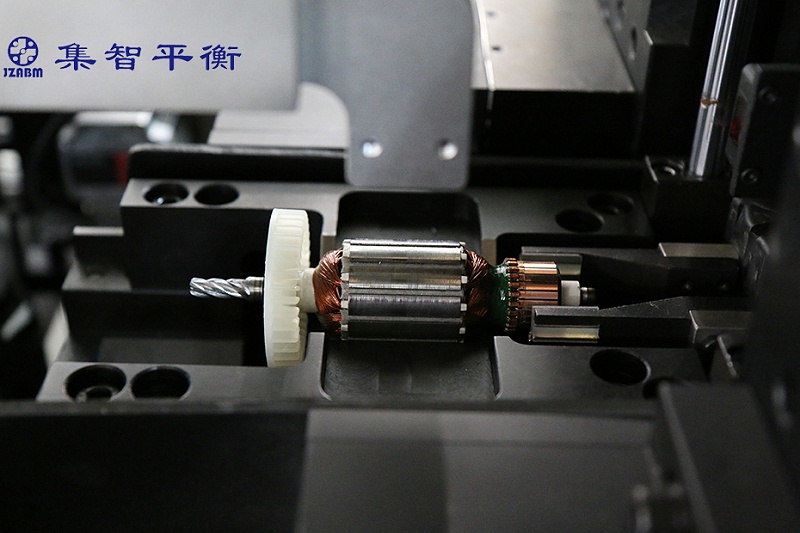

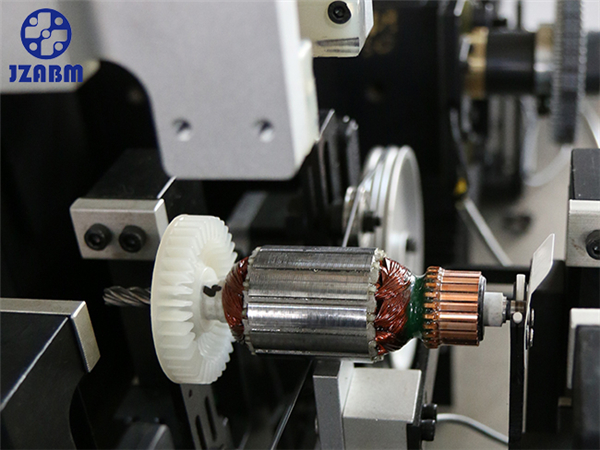

Hangzhou Jizhi two-position automatic balancing machine model: BDXSR-2WII-AX, mainly used for dynamic balancing correction of various micro and small wound rotors such as electric tools, Petits appareils électroménagers, automobile starting motors, etc; Applicable to rotors with workpiece outer diameter of 23mm~65mm, compatible with dynamic balance correction of some brushless motor rotors. The cutting table of this two-position full-automatic balancing machine is divided into single tool and double tool weight removal. There is one cutting table for single tool and two cutting tables for double tool. Different customers can choose the corresponding cutting table according to the characteristics of the balanced workpiece.

The main work flow of the R-type two-station automatic balancing machine is as follows:

1. Place the rotor on the test bench;

2. The test bench measures the size and angle of the initial unbalance of the rotor;

3. The manipulator carries the rotor to the cutting table;

4. The cutting table corrects the unbalance of the rotor;

5. The manipulator carries the corrected rotor to the test bench;

6. The test bench measures the unbalance and angle of the corrected rotor;

7. Judge the good and bad products according to the test results of the test bench;

The main features of the two-station automatic balancing machine are as follows:

1. Wide range of application, quick type change, suitable for small batch and multiple variety quick change;

2. Full-automatic measurement and weight removal, simple training can be used for work;

3. Chargement et déchargement manuels, Signal sonore et lumineux pour un jugement nuancé, one person can operate two sets at the same time; Fault alarm prompt, convenient for maintenance;

4. Il peut être équipé d’une ligne d’assemblage automatique séparée ou d’une ligne de production de rotor entièrement automatique;

5. Selon les caractéristiques du rotor, there are R V T and other weight removal methods available;

6. The main electrical components adopt international first-line brands, et les performances de l’équipement sont stables et fiables;

7. Système de mesure de haute précision avec support souple, high accuracy and good repeatability of measurement data;

8. Des droits de propriété intellectuelle totalement indépendants, Les produits spéciaux peuvent prendre en charge des solutions hautement personnalisées;

Machines d’équilibrage JZABM

Machines d’équilibrage JZABM