Fachadas:

- Pruebas de equipos, utillaje, Accesorios, etc. todos están diseñados y procesados con precisión, y se utilizan sensores de desplazamiento de alta precisión para garantizar la exactitud de las pruebas;

- Durante un proceso de corrección, La deformación en tiempo real del producto actual se captura con sensibilidad, y la mayoría de los productos tienen una tasa de corrección de más de 90%;

- El equipo adopta un control PLC completo, Deshacerse de la ruta de control informático industrial criticada por la industria, y garantizar la estabilidad del sistema de control del equipo;

- Se adopta un sistema de control que puede monitorear en tiempo real, y no se requiere intervención manual durante el proceso de enderezado;

- Tiene múltiples funciones y se puede personalizar de acuerdo con los requisitos del cliente, con un corto ciclo de personalización:

- El sistema puede guardar varios modelos de productos y realizar cambios de modelo con un solo clic, y el cambio de modelo de herramientas solo toma 10 acta;

- Información completa del aviso de alarma de situación anormal, Mantenimiento conveniente del equipo; 8. Se puede combinar con carga y descarga automáticas, sin supervisión manual.

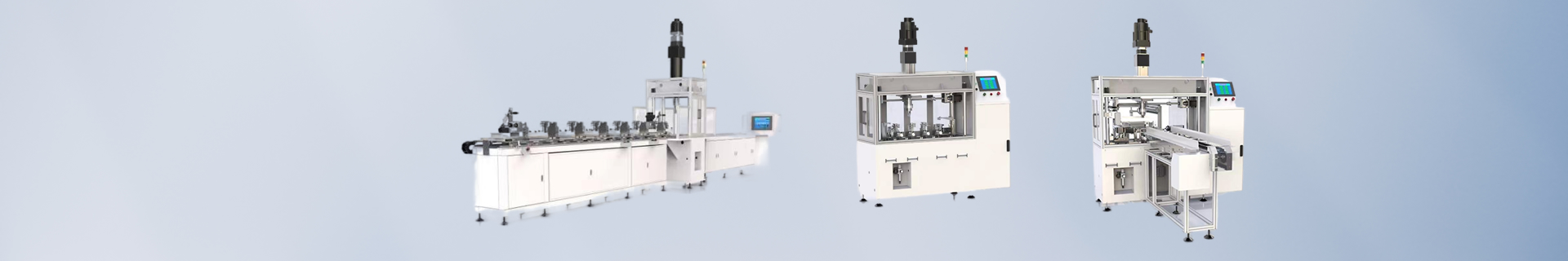

Máquinas equilibradoras JZABM

Máquinas equilibradoras JZABM