Palabras clave:

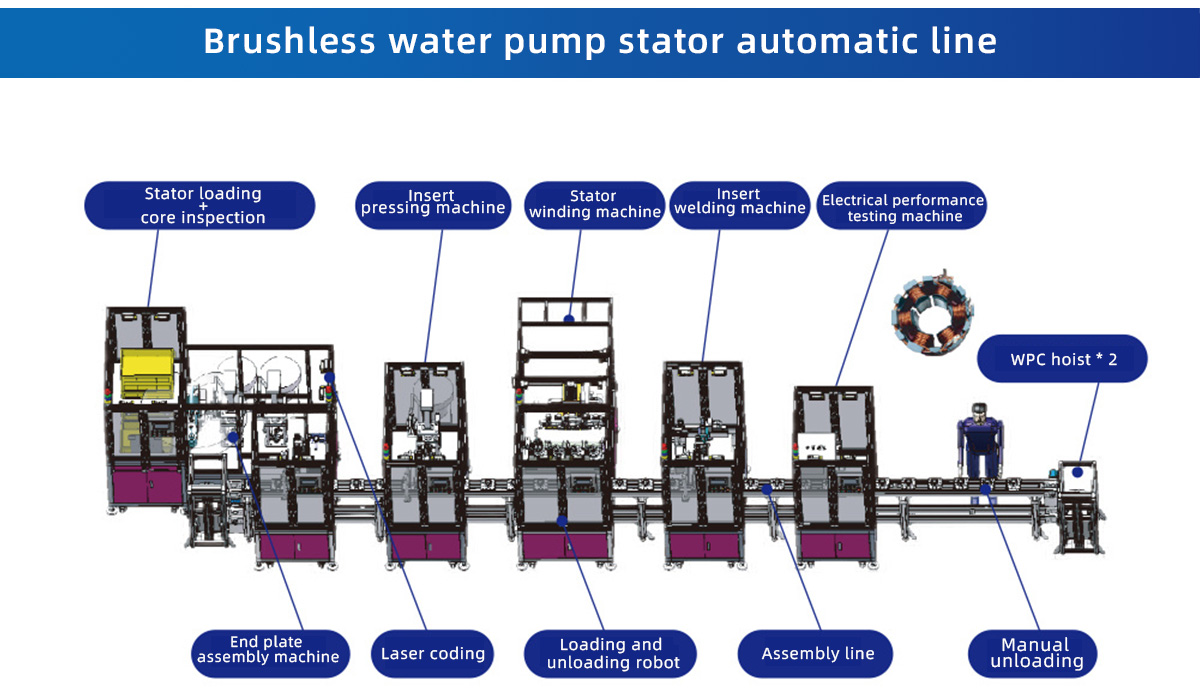

Water pump stator automatic production line

Water Pump Stator Production Line

Water pump motor stator production line

1.Stator core loading system: deliver the processed stator core to the stator assembly area through conveyor belt or other means;

2.End plate assembly system: install the end plates on both sides of the stator in sequence on the stator;

3.Stator pinning: provide the connecting terminals to the assembly area through the vibrating disk loading, and pick up the materials with the robot for pinning. Test the insertion height 4.after insertion;

5.Stator winding: Winding according to the winding process;

6.Terminal spot welding: weld the terminals and copper wires by resistance welding;

7.Detection system: conduct a number of electrical performance tests on the assembled stator to ensure that the stator’s performance indexes meet the required standards;

8.Packing system: the qualified pump stator is packaged under the material.

Proceso de producción:

- Stator core loading → stator visual inspection → upper and lower end plate assembly → laser coding → insert press fitting → insert inspection → robotic stator loading → stator winding → insert welding → phase ring assembly → electrical performance test → manual discharging

Máquinas equilibradoras JZABM

Máquinas equilibradoras JZABM