The answer is limited. Noise can be an indicator of poor rotor balance, but it cannot be the only basis for judgment. Firstly, the noise may not be caused by poor rotor balance. In mechanical equipment, noise can be caused by various factors, such as bearing failure, gear clearance, and motor speed. Therefore, even if the equipment noise increases, we cannot easily conclude that it is caused by poor rotor balance. Secondly, even the noise caused by poor rotor balance may not be significant enough. Noise may be affected by environmental noise, which cannot clearly indicate the degree of poor rotor balance.

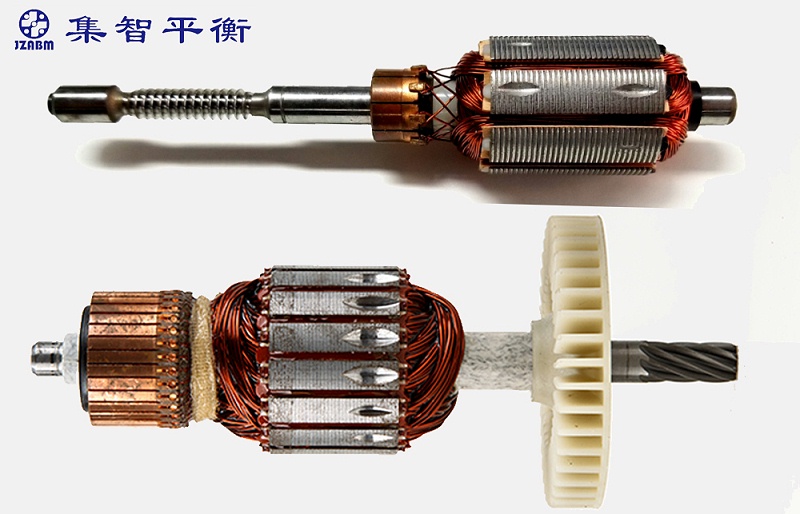

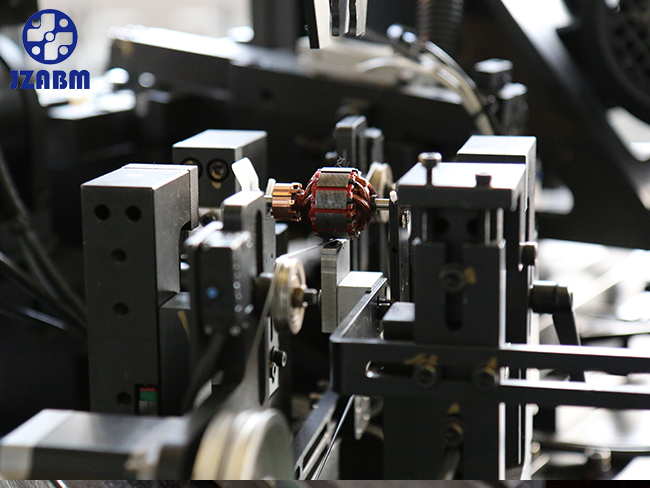

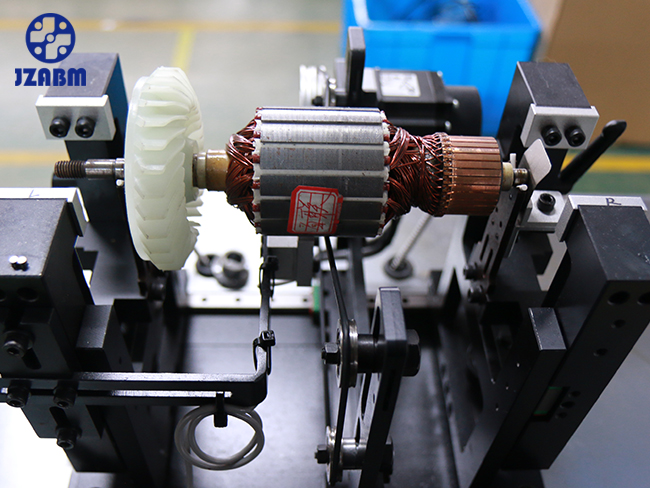

Therefore, we cannot rely solely on noise to determine the balance of the rotor. On the contrary, we need to use professional equipment and technology to monitor and adjust the rotor balance. Among them, dynamic balancing technology is a commonly used technique, which can adjust the balance of the rotor by adding or removing mass on the rotor to make the center of gravity of the rotor coincide with the axis of the shaft. In dynamic balancing technology, the use of Hangzhou Jizhi dynamic balancing machine can detect and adjust the rotor balance degree, thereby ensuring the normal operation of the equipment.

Of course, in daily maintenance, we can still use noise to preliminarily determine the balance of the rotor. However, it should be noted that noise is only a reference factor and cannot be used as the final judgment basis. In the case of noise from mechanical equipment, we need to combine other factors such as vibration, temperature, etc. to make a comprehensive judgment. If we suspect poor rotor balance, we should immediately shut down and undergo professional maintenance.

In summary, poor rotor balance cannot be judged solely by noise. Although noise can serve as an indicator, it has certain limitations. In order to accurately determine the poor balance of the rotor, a better method is to use a professional dynamic balancing machine from Jizhi for testing and analysis. These testing instruments can measure the vibration and displacement of rotating machinery at different speeds to determine whether the rotor is balanced. Through this method, the problem of poor rotor balance can be accurately detected and located, and appropriate measures can be taken to repair it, ensuring the normal operation of the machinery and extending its service life.

JZABM Balancing Machines

JZABM Balancing Machines