In an ideal situation, when the revolving body rotates and does not rotate, the pressure on the bearing is the same, and such revolving body is a balanced revolving body. However, in practical applications, due to various factors such as uneven materials or blank defects, errors generated in processing and assembly, and even unsymmetrical geometric shapes in design, various revolving bodies cause unbalance of revolving bodies. Even if the revolving bodies are statically balanced, the centrifugal inertial forces generated by each small particle on the revolving bodies cannot offset each other during rotation, resulting in unbalanced centrifugal forces, This leads to dynamic imbalance.

Rotor unbalance is a fault caused by eccentric mass or defect of rotor components There are many specific reasons for rotor unbalance, which can be divided into original unbalance, gradual unbalance and sudden unbalance according to the process of unbalance. The original unbalance is caused by the manufacturing error, assembly error, uneven material and other reasons of the rotor. If the dynamic balance does not meet the balance accuracy requirements when leaving the factory, large vibration will occur at the beginning of use. The gradual unbalance is caused by the uneven scaling on the rotor, the uneven deposition of dust in the medium, the uneven wear of particles in the medium on the blades and impellers, and the abrasion of the working medium on the rotor. The causes of rotor imbalance are generally divided into the following categories:

1. The shape of rotating parts is asymmetric

2. Tolerance on processing and manufacturing

3. Improper assembly and installation

4. Deformation of rotating parts during operation

5. Damaged and worn rotating parts

6. Foreign matters attached to rotating parts

Hazards of rotor unbalance:

Unbalance is a fault state caused by the non coincidence of the mass and geometric centerline (the center of mass is not on the rotation axis). The consequence of imbalance is to increase the additional load, which is one of the four common faults of equipment and parts damage. It is shown that the vibration value increases gradually with the extension of running time. The sudden unbalance is caused by the falling off of parts on the rotor or the attachment and jamming of foreign matters in the impeller flow passage, and the unit vibration value suddenly increases significantly and then stabilizes at a certain level. The dynamic imbalance will produce centrifugal force. The centrifugal inertia force acts on the machinery and its foundation through the bearing, causing vibration, noise, accelerating bearing wear, shortening the mechanical life, and even causing destructive accidents in serious cases. According to statistics, about 50% of mechanical vibration is caused by unbalanced force.

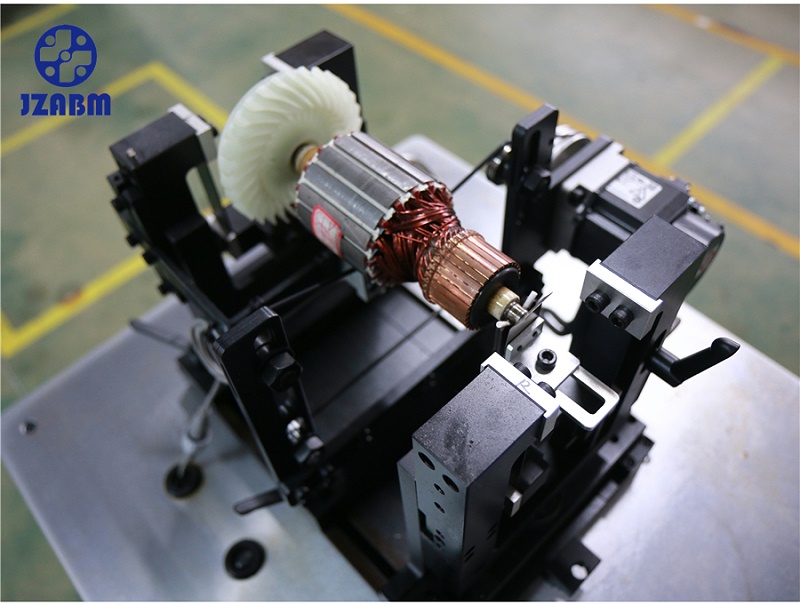

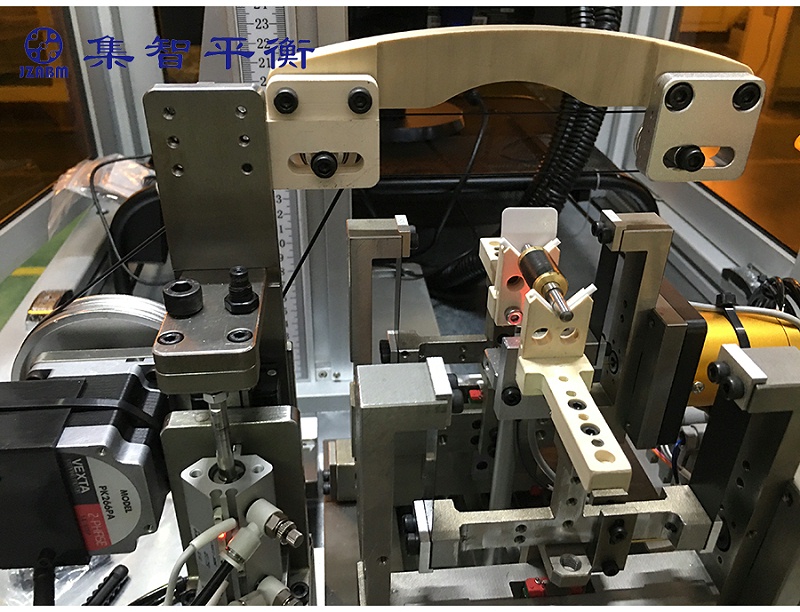

Therefore, it is necessary to change the mass of the moving part of the rotating machinery to reduce the unbalanced force, that is, to balance the rotor. Make it reach the allowable balance accuracy level, or make the mechanical vibration amplitude generated thereby fall within the allowable range, so it is necessary to detect the dynamic balancer.

JZABM Balancing Machines

JZABM Balancing Machines