The dynamic unbalance of the rotor is generated during the rotor processing. From the perspective of the rotor processing technology, analyze the main reasons for the rotor dynamic unbalance, and what are the processes and process control measures that have a significant impact on the initial rotor unbalance? Let’s learn about it with Jizhi.

1. Rotor iron core punching and lamination: Sampling check the thickness of the silicon steel sheet, punching burr, lamination tightness and unbalance, mainly through the quality control of the stamping die and the thickness control of the silicon steel sheet to limit the shaft bending caused by the large unbalance of the iron core Case. The stacked steel sheets can be turned and stacked. For example, the 12-slot rotor can be divided into three stacks, and each stack can be rotated 120 degrees.

2. Shaft pressing into the rotor core: The shaft pressing machine generally adopts pneumatic or hydraulic pressure. Due to the dispersion of the manufacturing process, the shaft may be bent due to excessive pressing force. By detecting the pressing force of the shaft and giving an alarm when the pressing force is too large, the shaft can be prevented from being bent. Whether the shaft is limited and fixed when the press head presses the shaft in, so as to prevent the verticality deviation when pressing into the iron core

3. The fan blade is pressed into the shaft: Reasonably design the tooling for the fan blade to be pressed into the shaft to ensure that there is no deformation during pressing. Does not move after insertion

4. Rotor winding: The double-flying fork symmetrical winding method is adopted, and the tension of the left and right flying forks is required to be basically the same, and the enameled wire is evenly stacked.

5. Insulating paint: the rotor is required to keep rotating during the dripping and cooling process, the paint viscosity is required to be moderate, and a large number of air bubbles cannot be generated

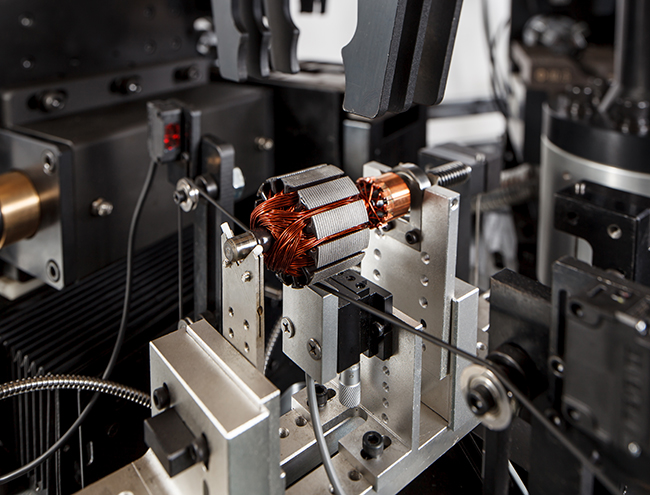

A rotor with a large initial unbalance may cause unpredictable danger when rotating at high speed, so it is necessary to perform dynamic balance correction on the rotor. Rotor dynamic balance is an extremely important process in the motor manufacturing process, which is directly related to whether the performance of the motor’s noise and vibration indicators meets the standards. Defects in the electrical design of the motor can also cause excessive noise and vibration, which are intertwined with the mechanical imbalance problem, resulting in extremely complex motor noise and vibration problems. Jizhi has different types of rotor dynamic balancing machines with different deduplication methods.

JZABM Balancing Machines

JZABM Balancing Machines