Answers to common question about testing station

The data fluctuates greatly, and the angle is also large.

There are two types of data runout, one is the runout between 5-10, and the second is the runout between 30-50-100.

The first type of runout is basically a mechanical interference. It can be checked whether the ceramic rod is worn, the steel pieces is worn, and the belt is cracked. The shaft end face of the commutator end of the rotor is uneven, not perpendicular to the axis, poor surface quality, and key grooves, etc.

The second is a data detection error. You can check whether the belt is rubbing against the slot sensor (common). In addition, if all channels have a runout of about 50, check whether the power supply voltage of the eddy current sensor is greater than 11.7V. This situation may be related to the factory voltage. Low-related, with occasional, irregular and periodical.

2. Unsuccessful Testing

There are generally two reasons for unsuccessful detection:

The first is unsuccessful speed increase, low speed, locked rotor, belt slippage, incorrect speed ratio parameter setting, damage to the slot sensor or iron filings, etc., which may cause this phenomenon.

The second is that the number of measurements exceeds the allowable number of times. Generally, it is caused by the vibration data runout exceeding the allowable jitter value. Adjust the sensor distance and clean the surface iron filings of the groove sensor, check whether there is any foreign matter on the rotor shaft, and judge whether the sensor is broken.

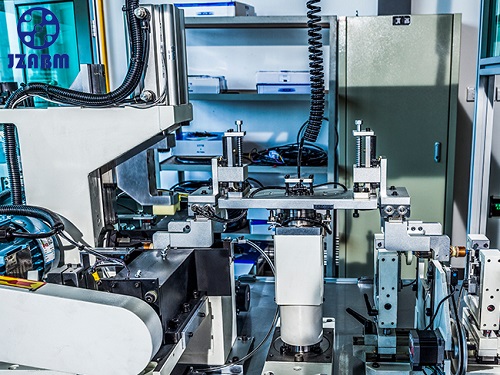

JZABM Balancing Machines

JZABM Balancing Machines