Number of correction planes

The number of correction planes and the selection of the axial position are based on the principle of the mode method, there are N method and N+2 method, that is, the number of correction planes is determined according to the mode order N to be balanced. The main principle is to use N+2 planes when balancing low-order modes, and use N planes when balancing high-order modes.

As for the selection of the axial position of the correction plane, the following two points should be considered: the balance weight can produce a greater balance effect under the corresponding vibration mode; the possibility and convenience of adding weight on the plane.

Balance speed

The goal of balance is to ensure that the rotor vibration meets the requirements within a certain speed range. For flexible rotors whose working speed is at least greater than the first-order critical speed, not only must the vibration at the working speed meet the requirements, but also the smoothly passing through the critical speeds during the start and stop process.

Vibration measuring point during balance

For the mode shape method, in theory, just take a vibration measurement point. For the influence coefficient method, the condition that the equation group has a solution is that the number of correction planes.

Try to add balance quality selection

No matter which balance method is used, the trial weight must be selected correctly before determining the balance weight. Whether the test and balance quality selection is appropriate will directly affect the success or failure of the balance test, especially in measuring the balance of the amplitude. When the rotor is severely unbalanced or the bearing vibration is too large, if the balance mass is too small, the bearing vibration will not change significantly, and the correct size and phase of the correction mass cannot be obtained.

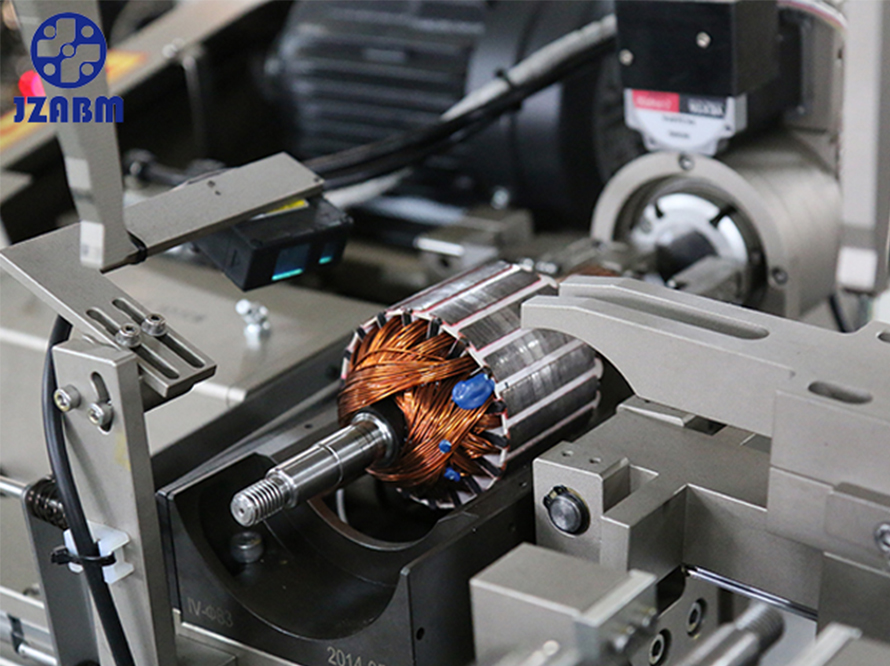

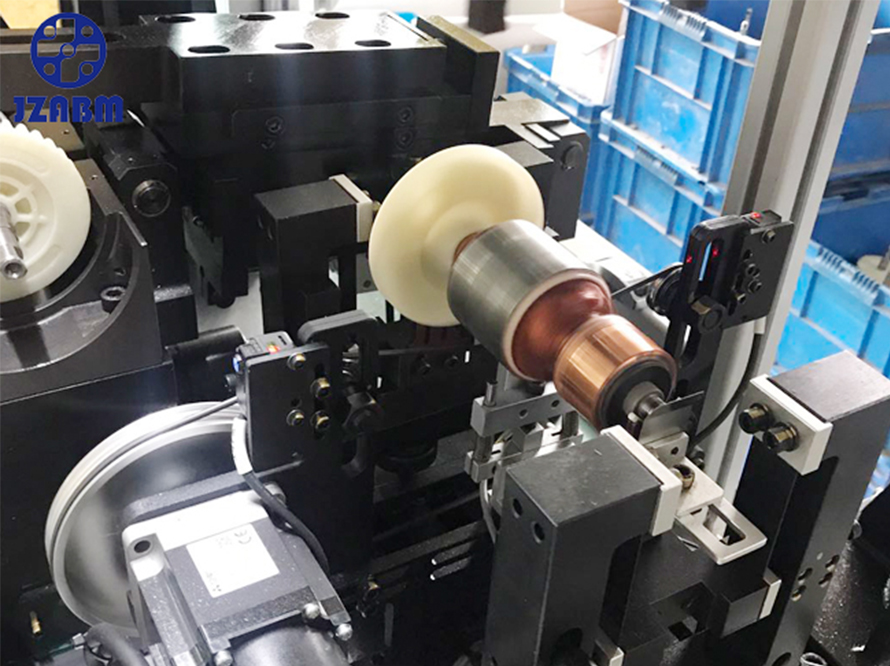

JZABM Balancing Machines

JZABM Balancing Machines